ALSO SEE OUR NEW FACEBOOK SECTION - NUNEATON MILLS & FACTORIES

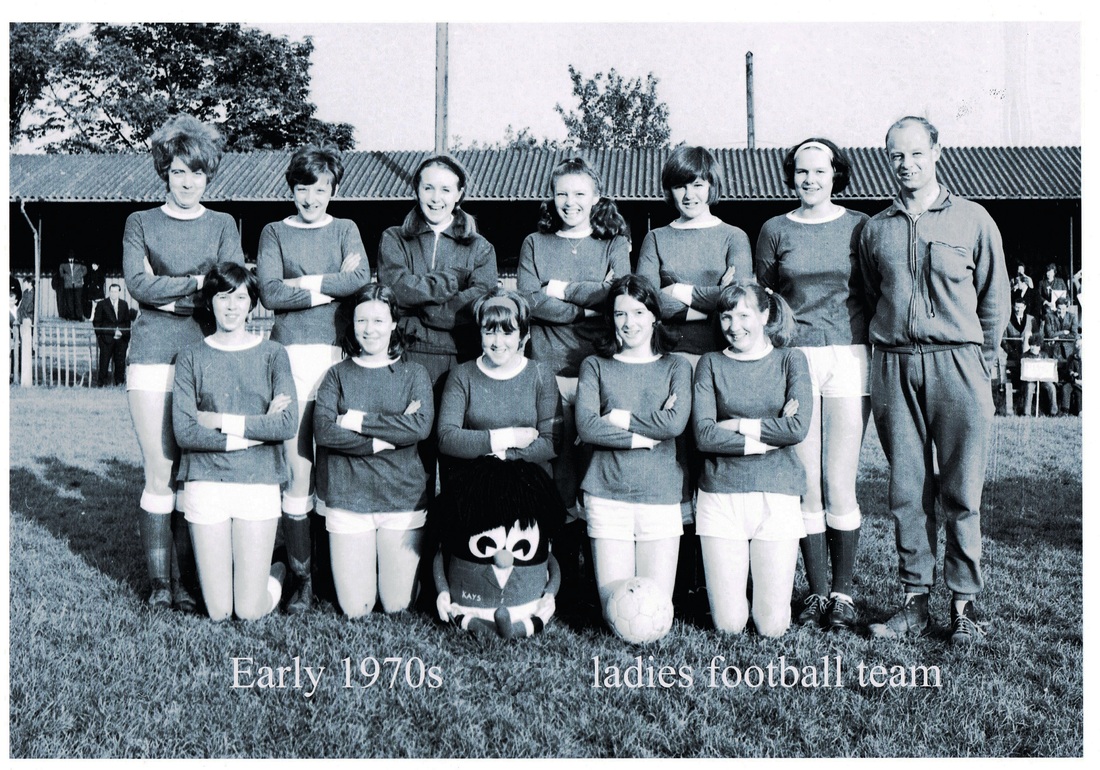

PHOTO FEATURE FROM NUNEATON's LOCAL INDUSTRIES - SHOWCASING STERLING METALS LADIES (scroll down the page to the section on Sterling Metals for a general view of the Attleborough works) Please let me know if you recognise anyone. PL

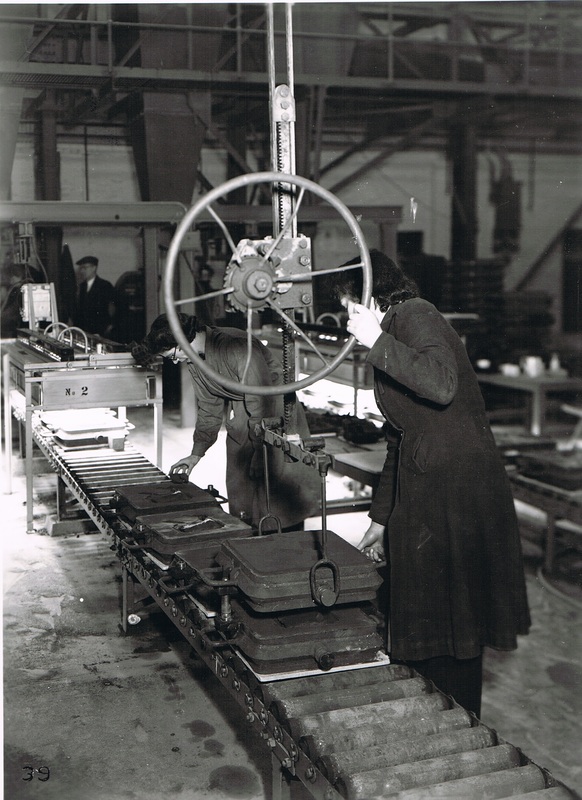

This lady appears to be filling small mould boxes with foundry sand which will then be sent to the foundry to be cast. Probably small aluminium components. Note she does not wear gloves for what must be a filthy job. What that oily foundry sand will do to her skin in years to come is open to debate. But she seems happy enough and the job seems "ideal" for a lady.

Sterling Metals continues down this page: _________________________________________________________________

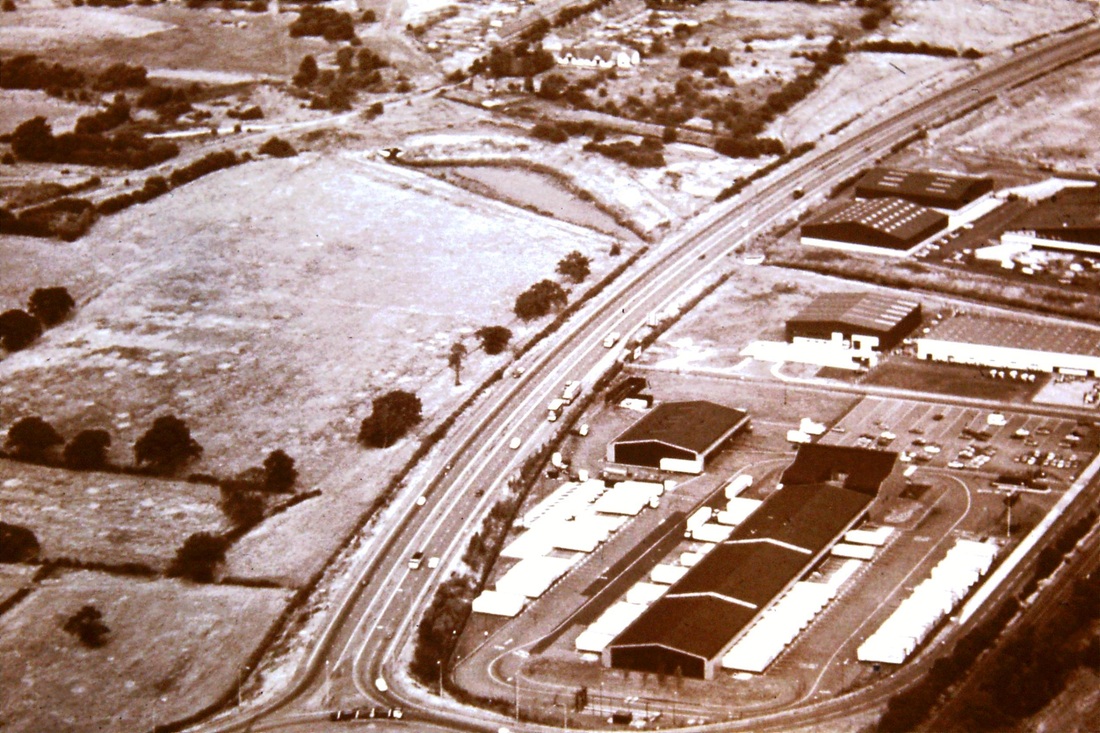

Distribution and Logistics for Local Businesses

Bermuda Industrial Estate in the 1970's. As built. Large areas of this estate are now unused, and factories vacant in 2014. The big distribution sheds on the right have been demolished and the site is empty. Nuneaton and Bedworth's claim to be a distribution hub has been diminished by the gradual reduction of businesses in the area, despite its enormous potential as the most central Borough in England.

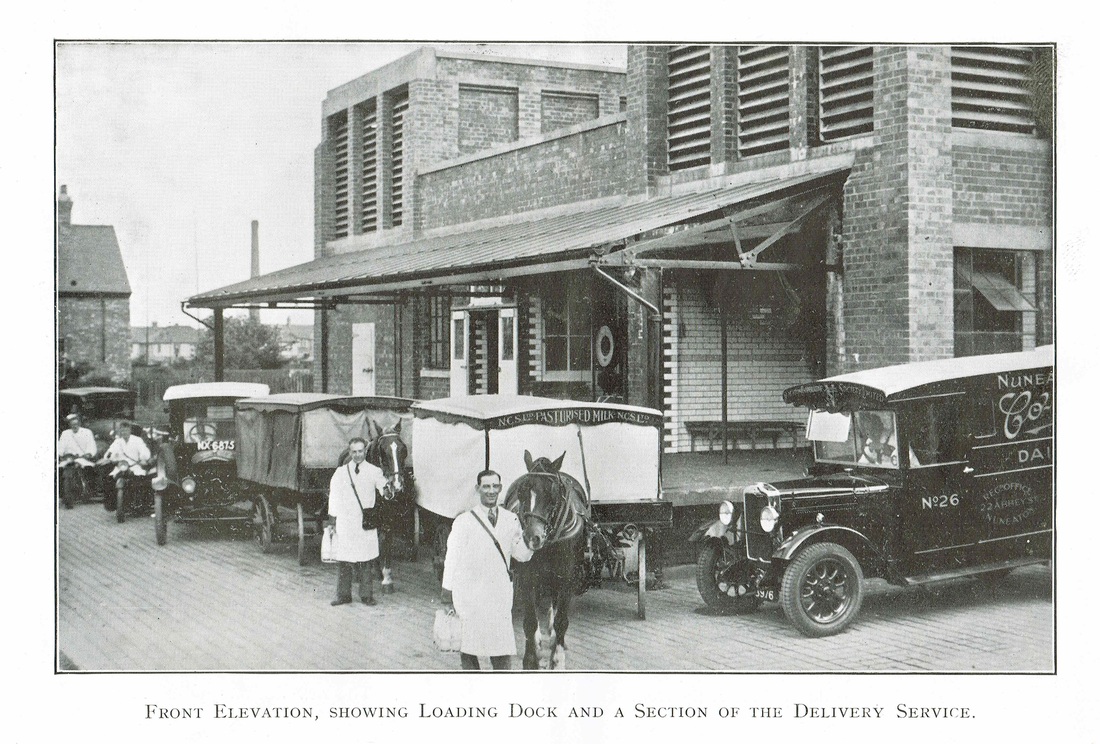

Nuneaton Co-Operative Society

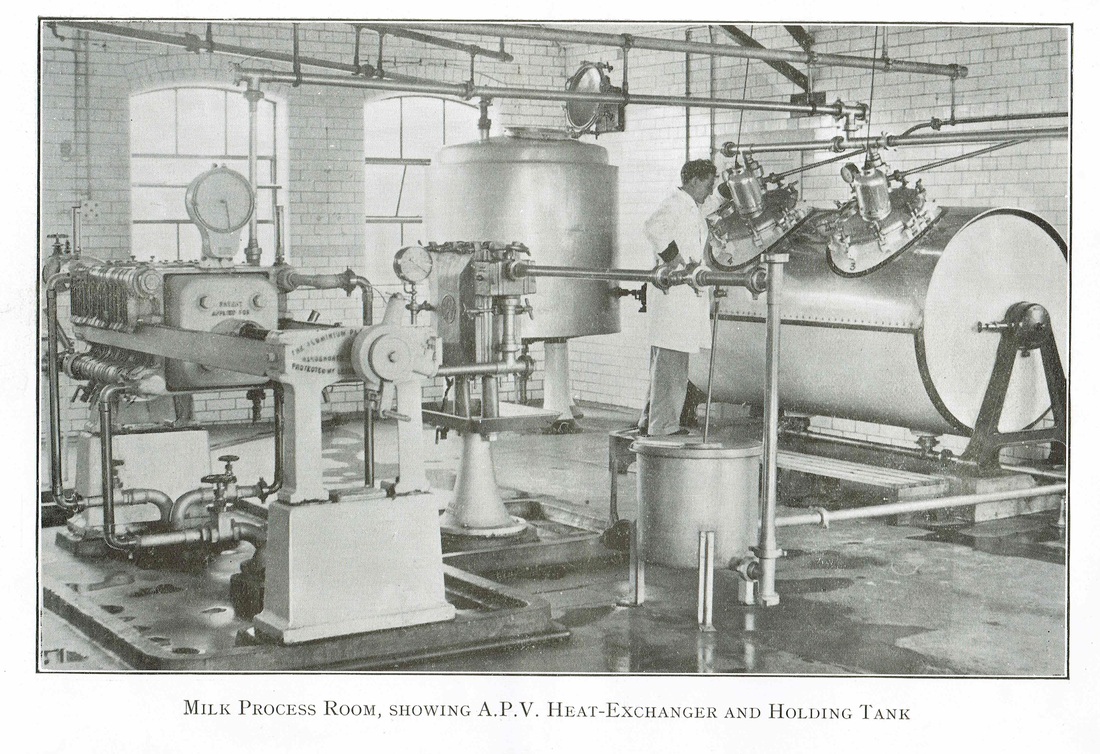

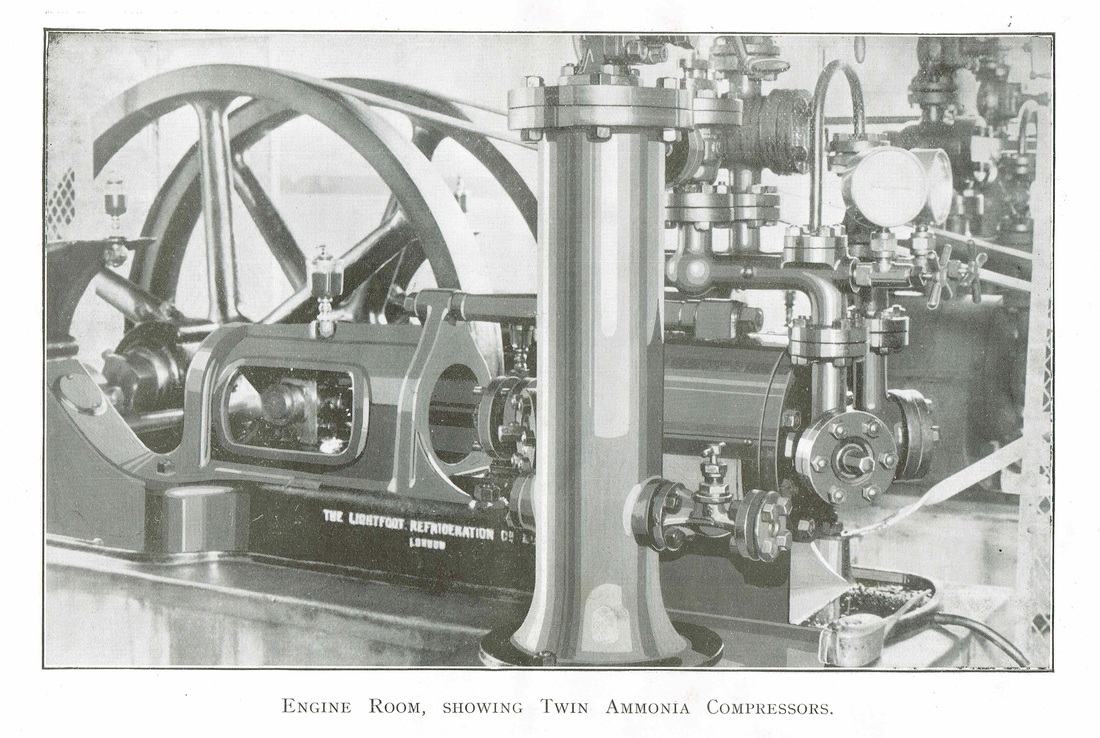

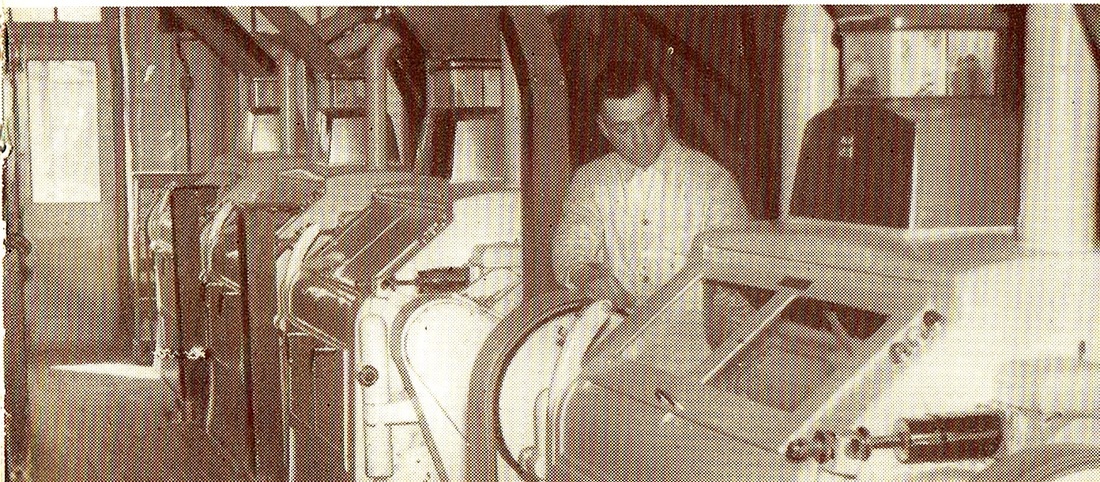

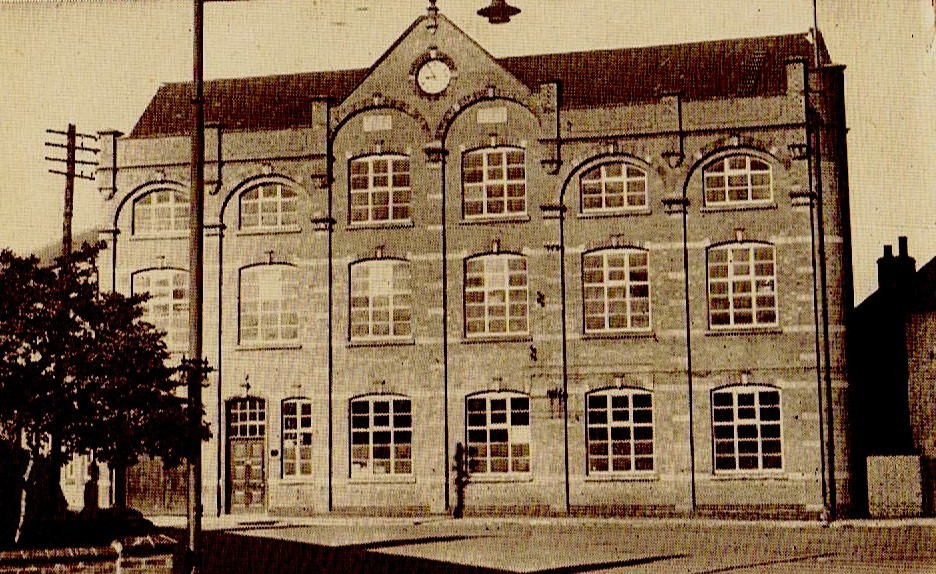

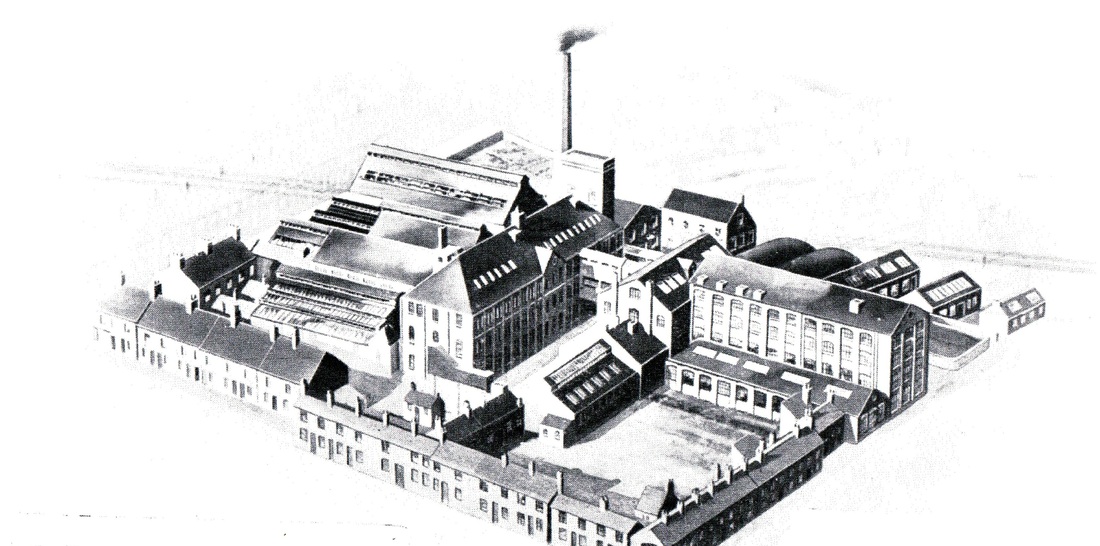

The Nuneaton Co-Operative Society Dairy was located in Merevale Avenue and was founded in 1926. It soon became apparent that the plant needed to be extended to cater for the large increase in the demand for milk throughout the district. An extension was started in 1930 and the new Model Dairy opened officially on Saturday, July 16th, 1932. On opening the capacity of the plant was 20,000 gallons a week, and in 1932 10,000 gallons a week was produced. The new dairy supplied milk as well to the Lockhurst Lane Co-Operative Society. The architect for the project was Mr. H.N. Jepson of Nuneaton and the contractors for the building work was Taberer & Co. The milk processing plant was let to a number of specialist process plant specialists. A laboratory was also set up. Local free lance milk men also obtained their bulk supplies from the dairy. (Tom Burgoyne Collection, courtesy Ian Burgoyne)

Nuneaton Flour & Provender Mill

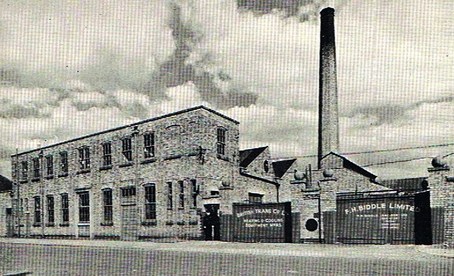

F.H.Biddle Ltd. & British Trane Co. Ltd.

The premises of F.H.Biddle and British Trane Co. Ltd in Newtown Road, Nuneaton. Heating & Ventilating Equipment manufacturers. Biddles started in London in 1929 and moved to Nuneaton in 1946. The businesses operated as two separate companies. British Trane made the equipment which F.H.Biddle then sold to the trade. They moved to St. Mary's Road in 1985. The premises we see here were demolished and replaced by the retail park now occupied by Curry's and Asda.

Hall & Phillips, Meadow Street, Nuneaton. Manufacturers of Hats

Rufus Jones Elastic Web Works, later Lester & Harris, Attleborough.

The Elastic Web works erected in 1910 on Attleborough Green, started in the 1870's (!878 is mentioned) and was originally owned by Rufus Jones. Their business was the manufacture of elastic webbing for shoe gussets, corsets, undergarments, braces, straps for race horse chandlery etc. utilising the redundant skills from the former silk ribbon industry. In 1938 it became part of Lester & Harris, a company based in Park Street, Coventry. Some Attleborough elastic web weavers went to Brockton, Massachussets to work in the shoe trade there. There was an elastic web works in Brockton - The Hub Gore Company which benefited from the skills of Attleborough elastic web weavers. Lester & Harris set up a new business in Queensland, Australia which was registed as Lester & Harris Pty on 22.6.1950 and the equipment from the Attleborough factory was crated and sent to Queensland. This Mill was demolished subsequently and the Co-Op retail store car park occupies the site today.

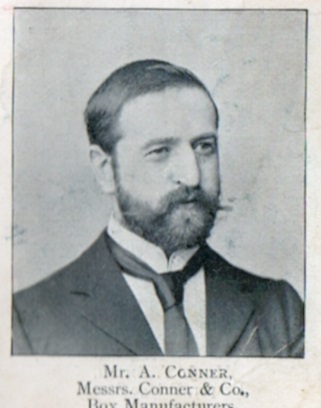

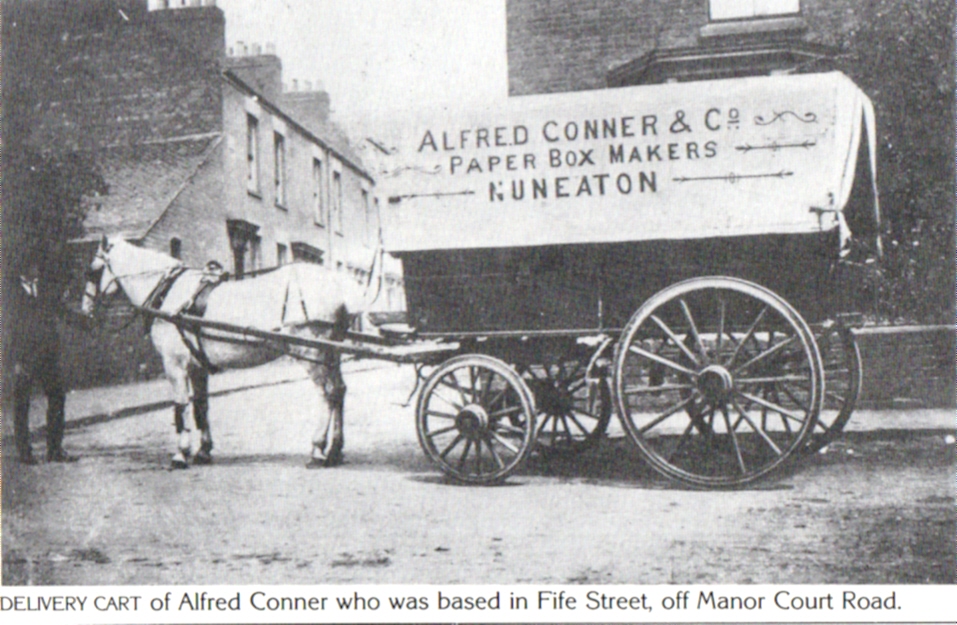

Alfred Connor & Co. Ltd., Cardboard Box Manufacturer

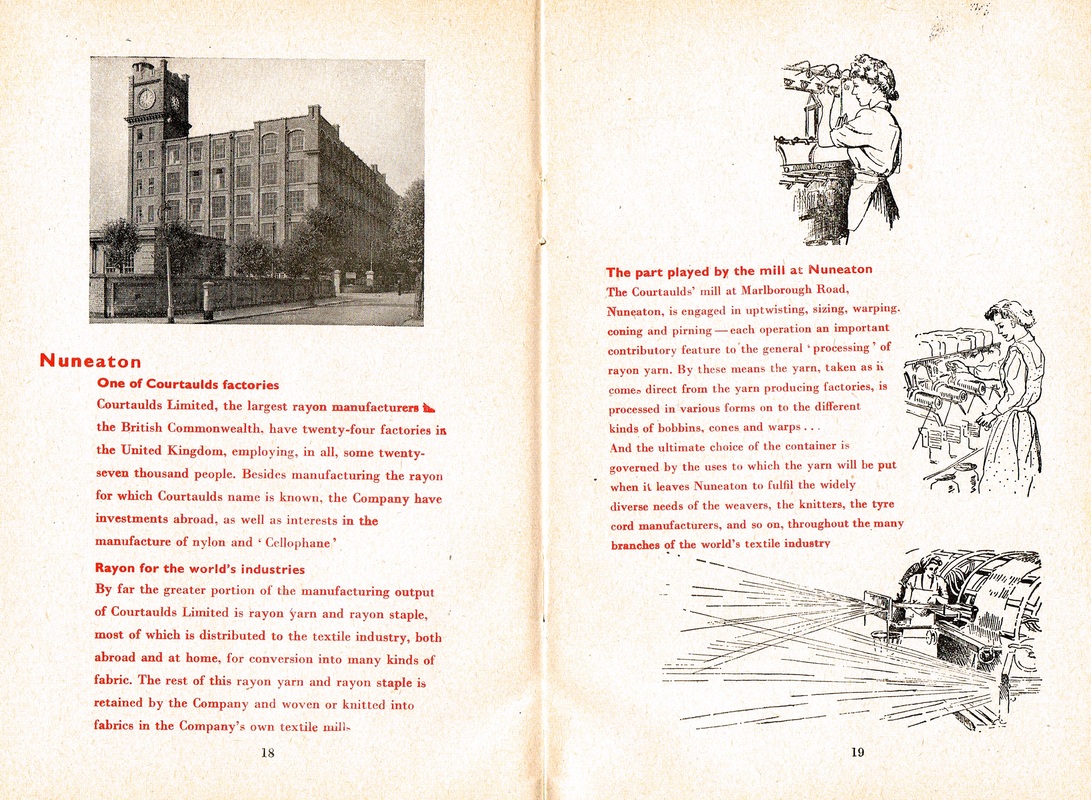

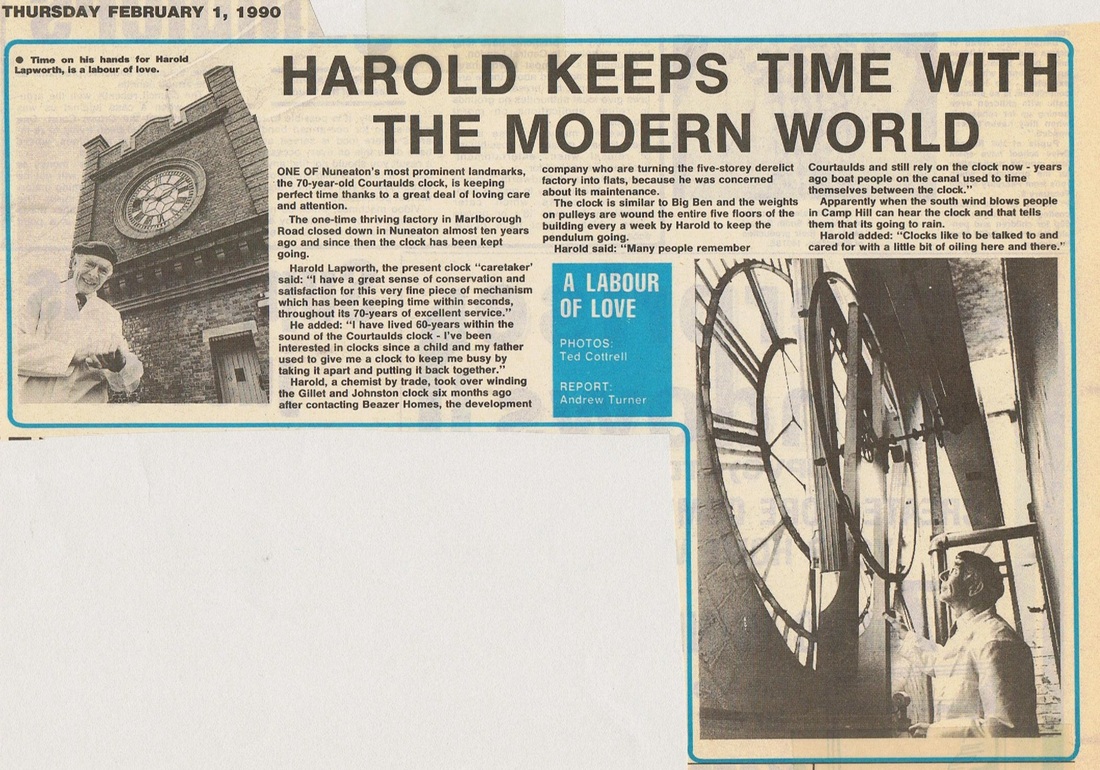

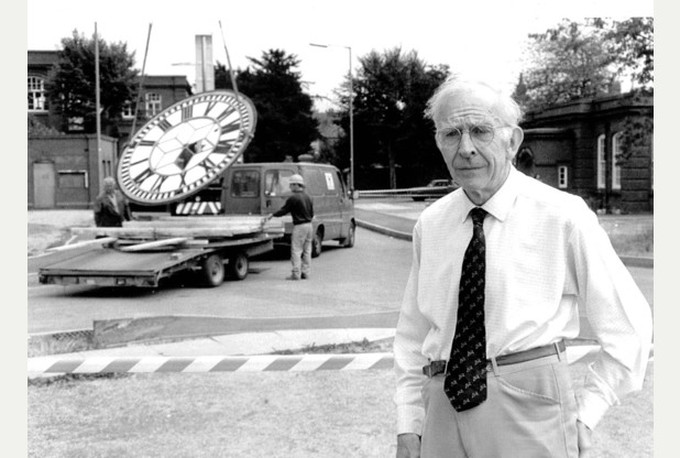

Courtaulds Mill. With its famous clock.

Courtaulds factory used to dominate the Nuneaton skyline. Here it seems to float like a stately galleon in the mist over the rooftops of the town. The factory was started to be built just prior to WW1 but work ceased due to the war and was restarted immediately after and the factory completed by the early 1920's. It employed thousands of hands mostly women, and was a valuable contributor to the local economy.

Courtaulds mill newly built in the 1920's probably about 1926 when one of the Nuneaton newspapers commissioned a Flying Club to carry out an aerial survey of the town recording a comprehensive record of the area. Invaluable to us today. The mill fronts Marlborough Road. Nearer to the right of the picture is Bracebridge Street whilst in the foreground running left to right is Princes Street. At that time this end of town was newly developed and you can just see the old fields which were now being covered over by new housing. At one time Nuneaton Town Football Club played on a field in Marlborough Road called Daffern's Field.

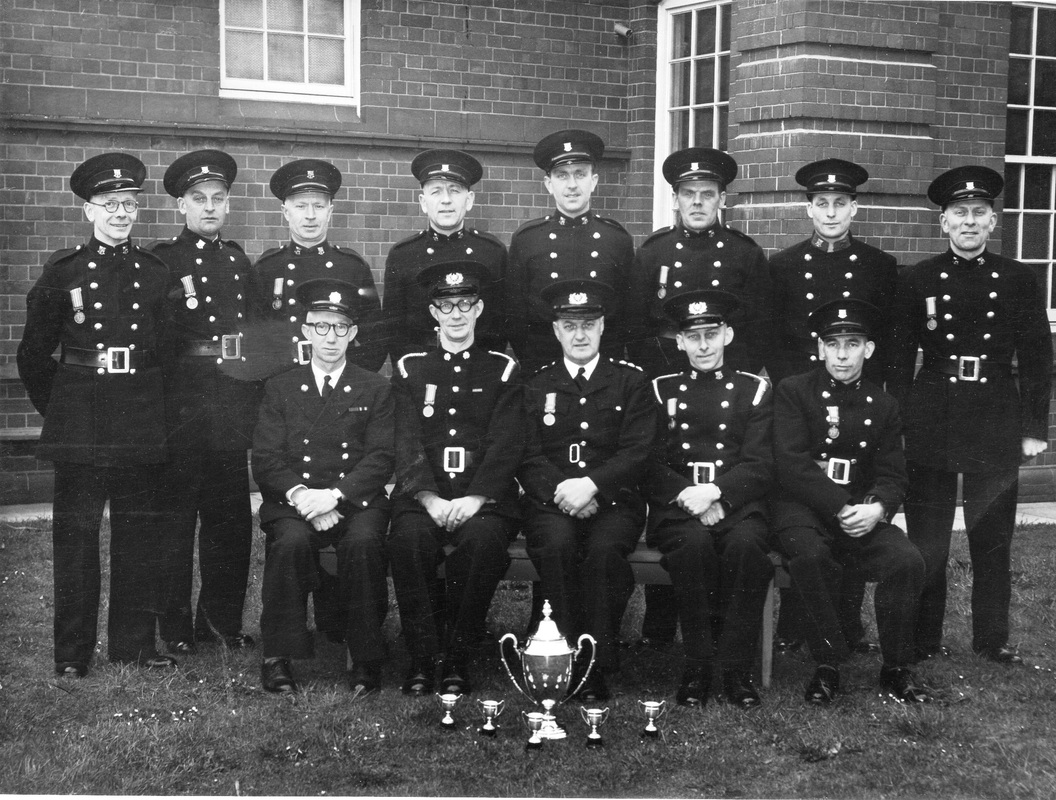

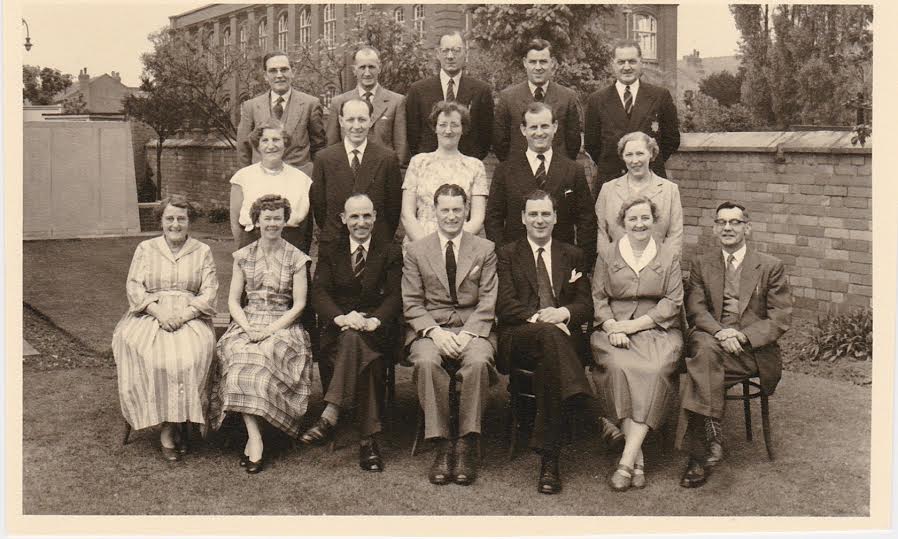

The senior staff of Courtaulds, Nuneaton. Back row centre: ?, ?, Mr. W. Beamish (Packing & Despatch Manager), ?, Mr. A. Lowe (Fire ooficer). Middle Row: Left: Miss May Barden,(head of training school), ?, ?(sickness stenographer), Mr. R. Farndon, Engineer's Office, Bottom Row: Left to Right: ?, ? shop steward, Mr. E. Sutton (Engineers Dept.) Mr. H.C.Rooney (Works Manager), Mr. J.H.Symons (Labour Officer), ?, Mr. T.Preston (T&GWU Representative and Shop Steward). (Courtesy of Stan Rooney).

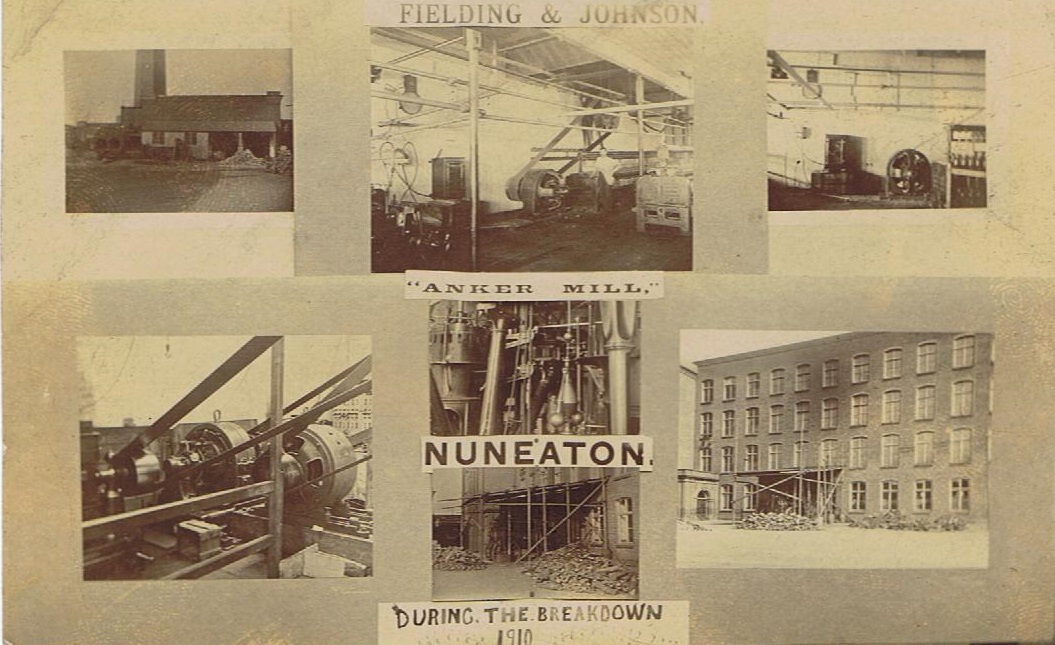

Fielding Johnson's Anker Mill in Nuneaton. A business established in Leicester in 1720.

Fielding Johnson's factory in Attleborough Road dominated the skyline. The mill was started as a cotton manufacturer, The Nuneaton Cotton Spinning & Weaving Co. Ltd, an enterprise of Lancashire mill owners was formed in 1860 (Registered 9th October 1860) and the new mill was erected and completed in 1861 at a cost of £60-70,000. The capital of the new company was £100,000 with 2770 shares amongst 234 shareholders. In 1877 the business was re-constituted as The Trent Cotton Milling & Manufacturing Co. Ltd (registered 24.11.1877) with a capital of £30,000 with 13 shareholders:

James Sawley Brown of Manchester

William Brown of Little Bolton Hall, Eccles

Annie Brown (his wife)

Edward Burgoyne of Southport

William Joseph Booth of Manchester

Henry Dean of Salford

Richard Fisher of Preston

Robert Atkinson Estrigge of New Brighton

Frank Rooley of Liverpool

Henry James Legge of Birkenhead

George Ormerod of Southport

Thomas Ormerod of Bury

Peter Ormerod of Shaw, Oldham

Benjamin Fisher of Standish Hall, nr. Wigan.The mill had originally been bought for £13,500 by Mr. Edward Burgoyne for £13,500 in 1877, and Mr. Burgoynes family were connected with the mill for 108 years when his grandson Thomas Burgoyne retired.

There was serious strike in 1883 when the mill employed 500 people. This was due to a reduction in wages due to the company's financial difficulties at the time. There was a slump in the cotton trade between 1883 and 1885. The firm closed in 1885 and was wound up on 28th September 1886. The mill was originally located here to alleviate distress in the silk ribbon industry. The mill was taken over by Messrs Fielding Johnson of Leicester in 1886. A business founded in 1720 processing wool. This new manufacturing operation was very successful and Fielding Johnsons traded in Nuneaton for nearly one hundred years. Latterly processing wool for the knitting trade. The mill employed 4-500 people.

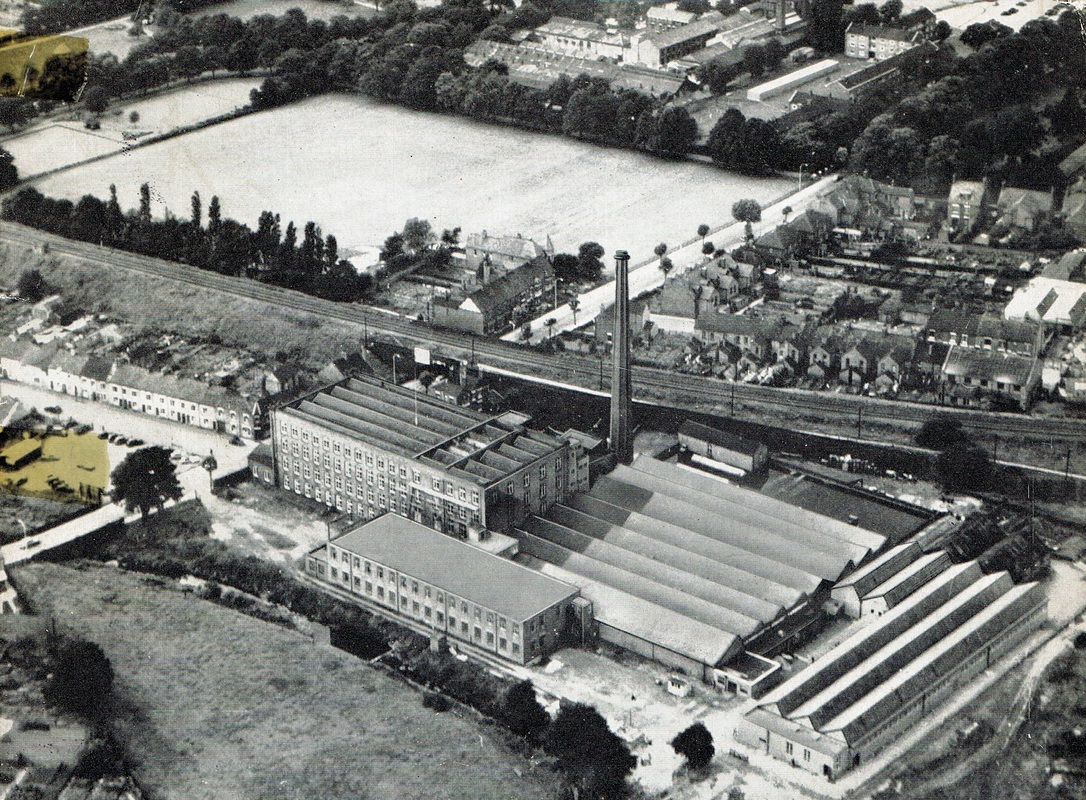

Fielding Johnsons - an aerial view. Attleborough Road traverses left to right and the road going off to the left is Seymour Road. The railway line between Nuneaton and Coventry crosses from left to right. The full extent of King Edward VI Grammar School is on the left half of the photo with the park beyond.

(Tom Burgoyne Collection)

Fielding & Johnsons was the reason this photo was taken and the full extent of this extensive local employer can be see, The River Anker runs along side the mill. Attleborough Road runs across the centre of the picture. The Nuneaton-Coventry railway line traverses the picture from top to bottom. The back of Nuneaton loco shed can be seen. The road leading off from Attleborough Road in front of the mill is Seymour Road with Moorehouses Jam factory was here. King Edward Grammar School playing field on the left centre. The picture was probably taken in the 1950's.

(Ruby Atkins Collection)

Fielding Johnson's staff from Tom Burgoyne's collection but we know so very little about the people depicted here. Can you help with identification?

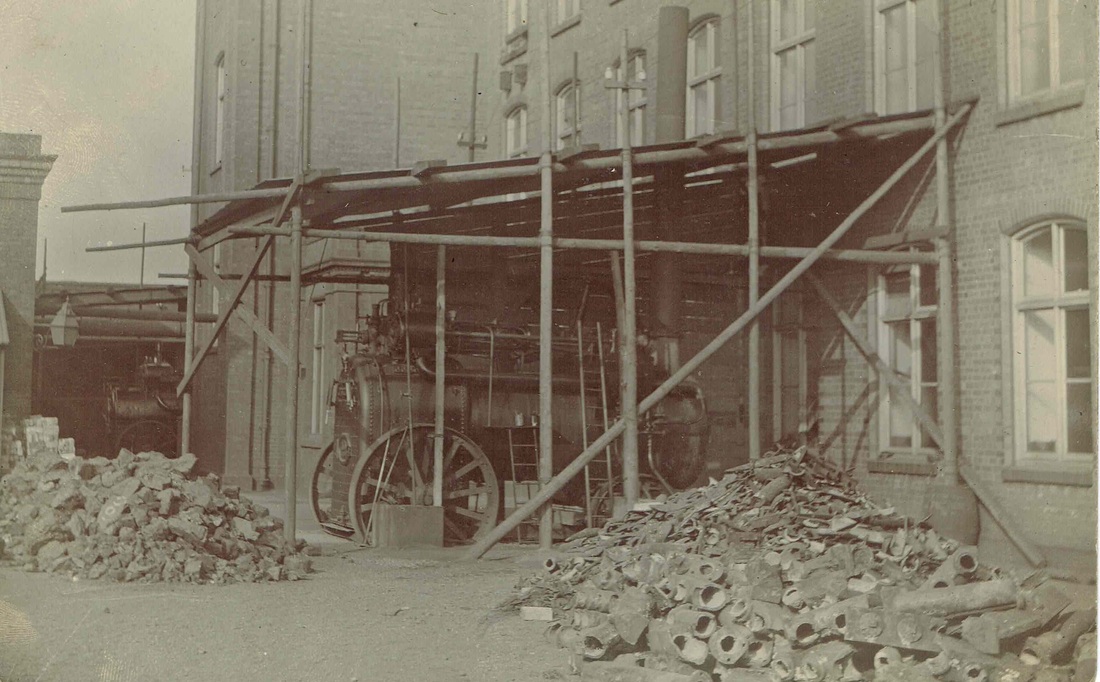

In 1910 there was a breakdown in the massive steam engine which drove the machinery at Fielding Johnsons so that two mobile steam engines had to be hired in temporarily in order to drive various machines. Both can be seen here. One tucked away in the background. These were used to drive machines in the Bottom Prep. shop, the Card Room, and the Back Wash. There is a large pile of coal on the left to fire the engine and a big pile of scrap cast iron pipework on the right recovered during the installation of the new steam engine. (Tom Burgoyne - Ian Burgoyne Collection)

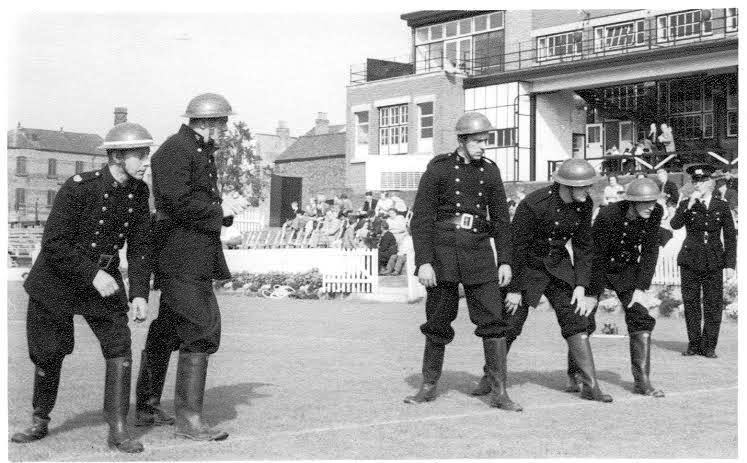

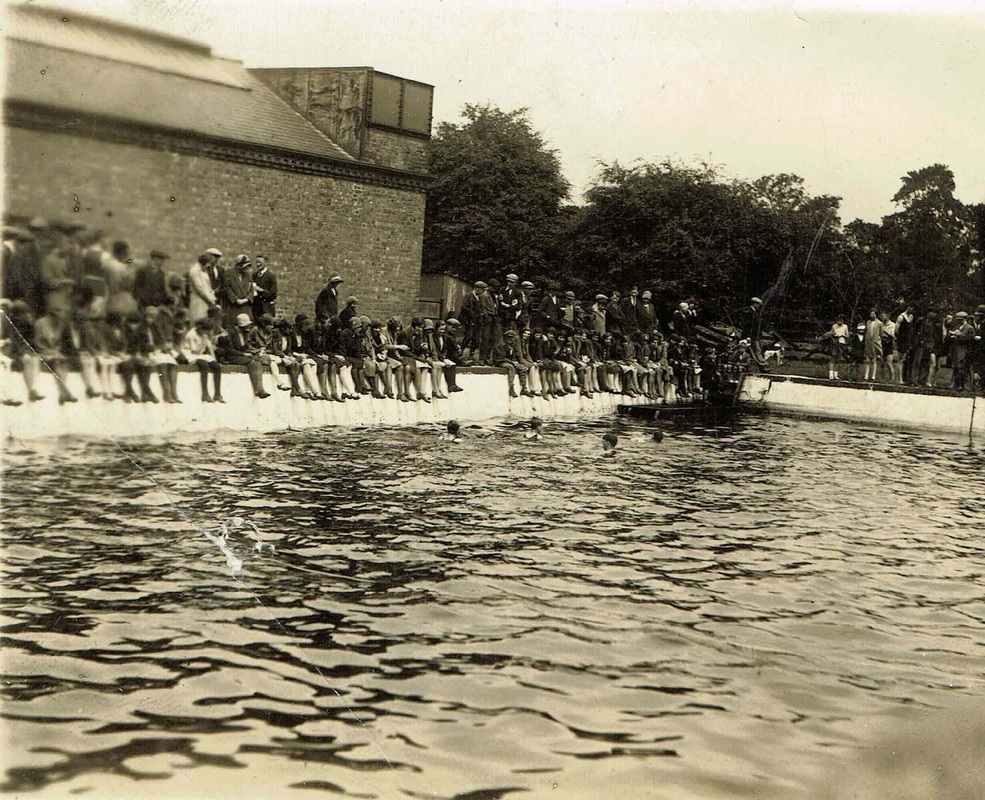

Fielding Johnson's factory had a large tank used to receive the water from the steam boilers Annie And Elizabeth and to cool the water before it was discharged into the River Anker. It was used by the Anker Mills Swimming Club and local schools used it as well. These photos were taken at a swimming gala there in the 1920's. Water from the river was used to condense the steam from the boilers and then cooled before discharge back into the river. The pool was taken out of use in 1932 due to damage in the 1932 flood and never repaired. The pool later was covered in a new part of the factory. (Tom Burgoyne, Ian Burgoyne Collection)

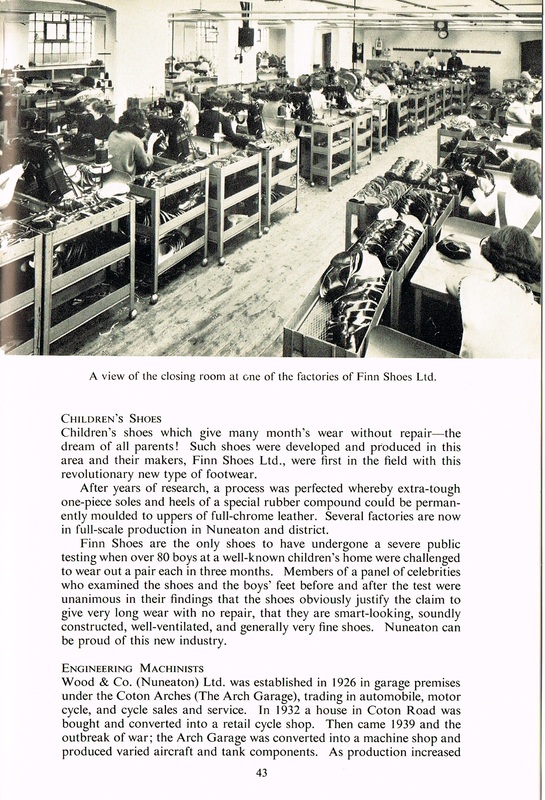

Finn Shoes Ltd., Weddington, Nuneaton.

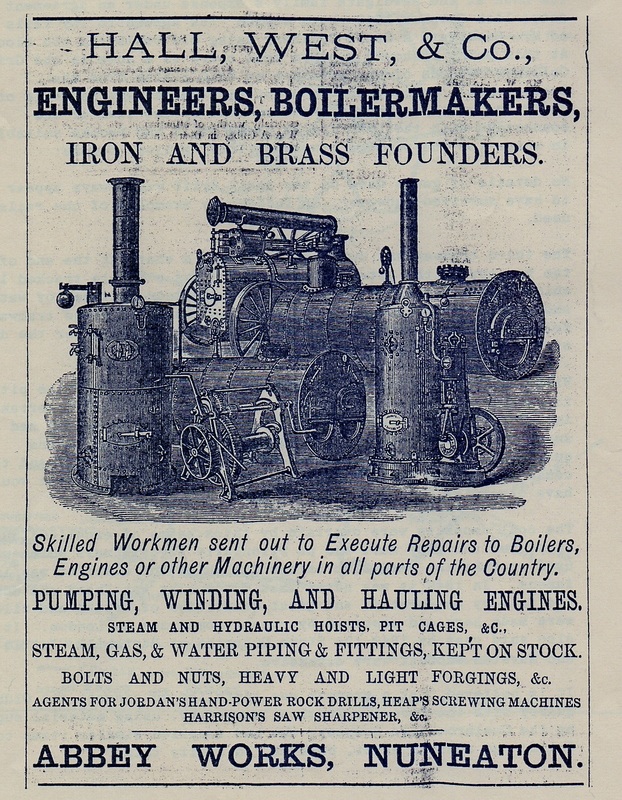

Hall West & Co. (Predecessors of Nuneaton Engineering Ltd.)

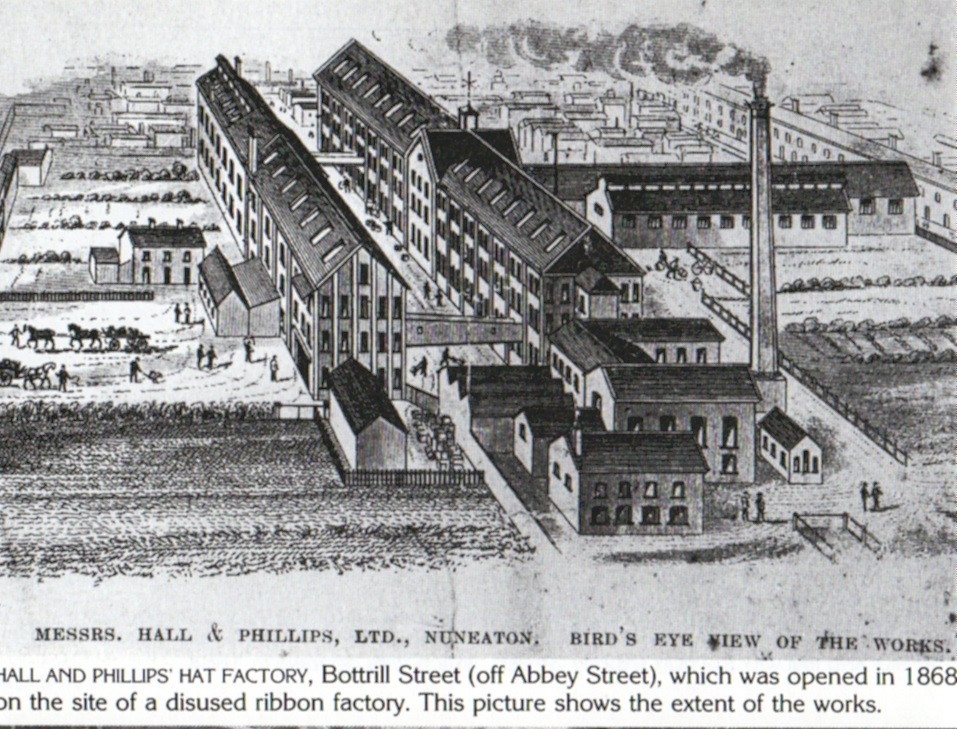

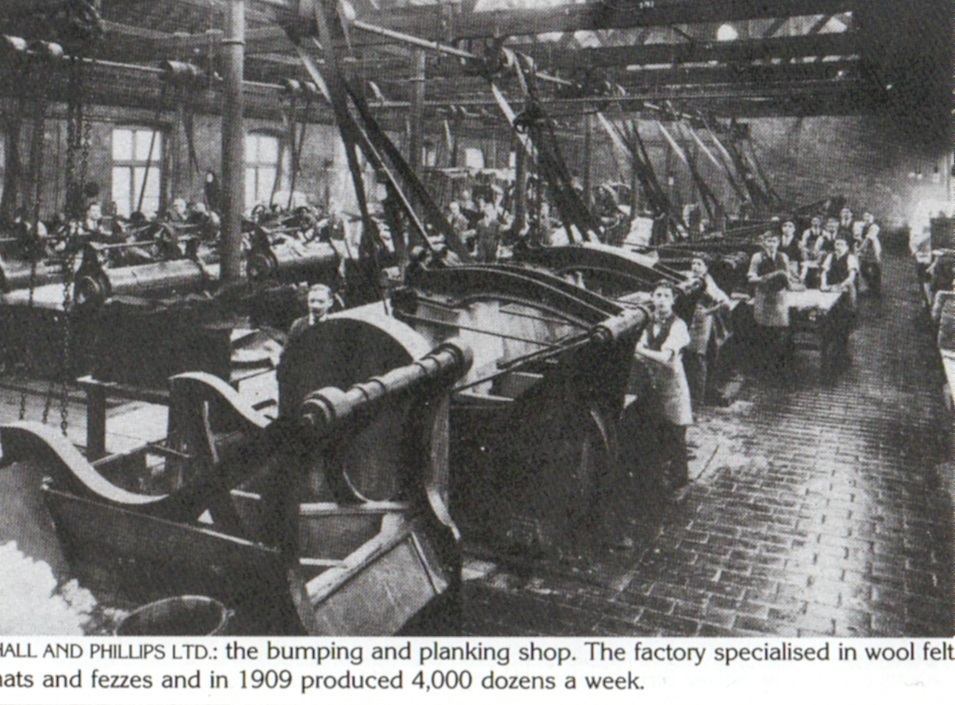

Hall & Phillips Ltd. Hat Manufacturers

It is hard to imagine the wide and diverse trades carried on in the Nuneaton area at one time. This is Hall & Phillips factory in Meadow Street from a print about 1910. The works was also shared with the Nuneaton Engineering Company at this period who made a wide variety of equipment for breweries, the mining and brickmaking industry etc. Hall & Phillips, however, made felt hats. It was a trade transplanted from the nearby hat manufacturing town of Atherstone. The business was originally started about 1731 by Joseph Willday and traded until 1853 in Atherstone when it was incorporated as Hall & Phillips. The entire business transferred to the Abbey Mills in Meadow Street, Nuneaton in 1868. William Silver Hall also owned an engineering business from the same premises, which he later sold to Stanley Brothers which continued to trade as the Nuneaton Engineering Co. As you can see from this picture Hall & Phillips made a wide variety of hats and had a capacity of 2-3000 hats per week. In 1908 they made 100 new styles for ladies and supplied both genders and all age groups. During World War 2 they supplied 1 million hats to the armed services. On 10th July 1932 they were honoured by a visit from the Prince of Wales After the factory closed as a hat manufacturer the mill and outbuildings were divided up into smaller units, one of whom made wooden car dash boards for the Coventry car manufacturers. The factory went up in a massive fire in 1967.

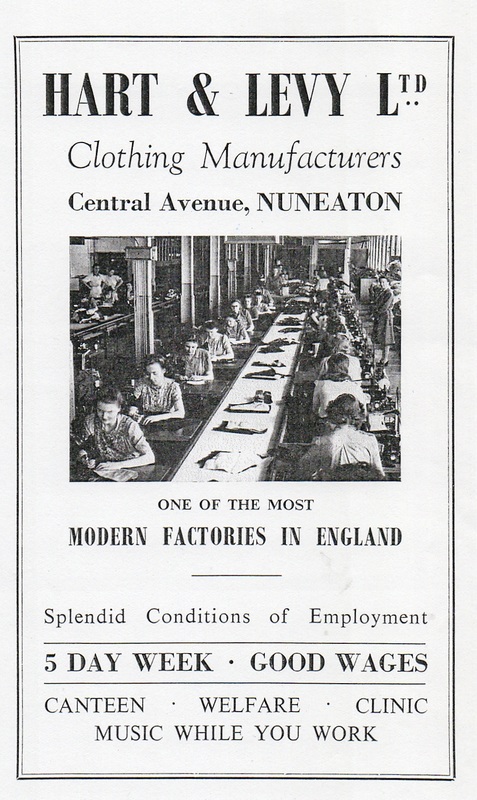

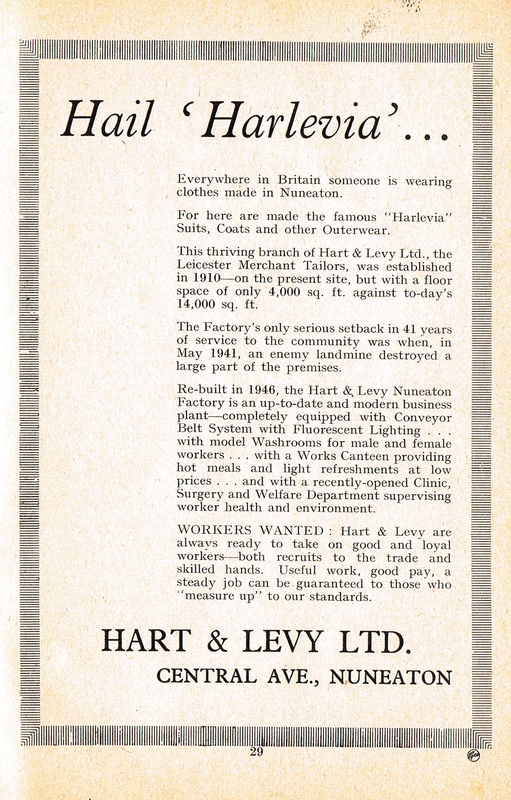

Hart & Levy Ltd.

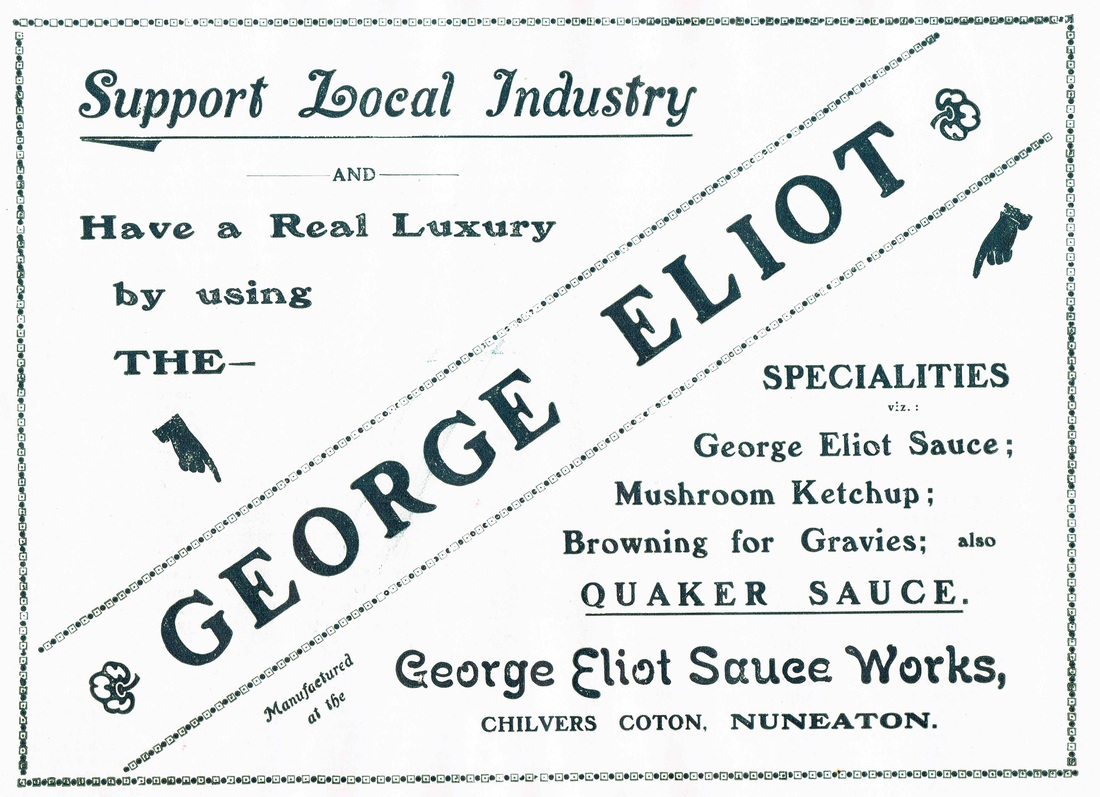

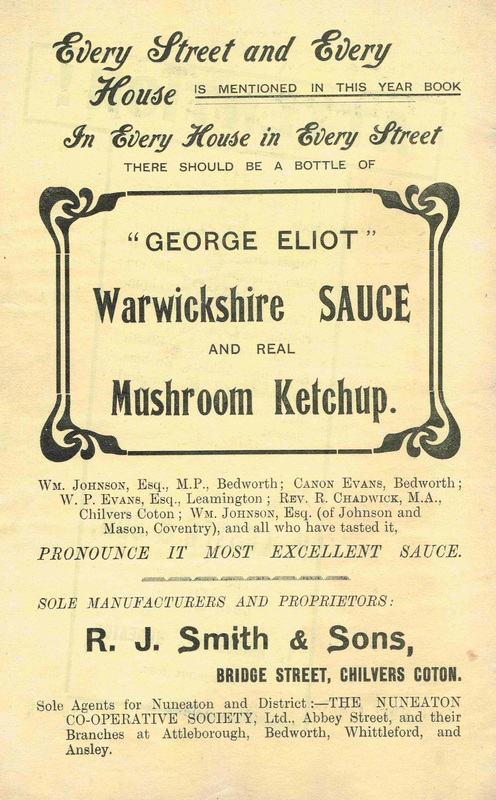

The George Eliot Sauce Works

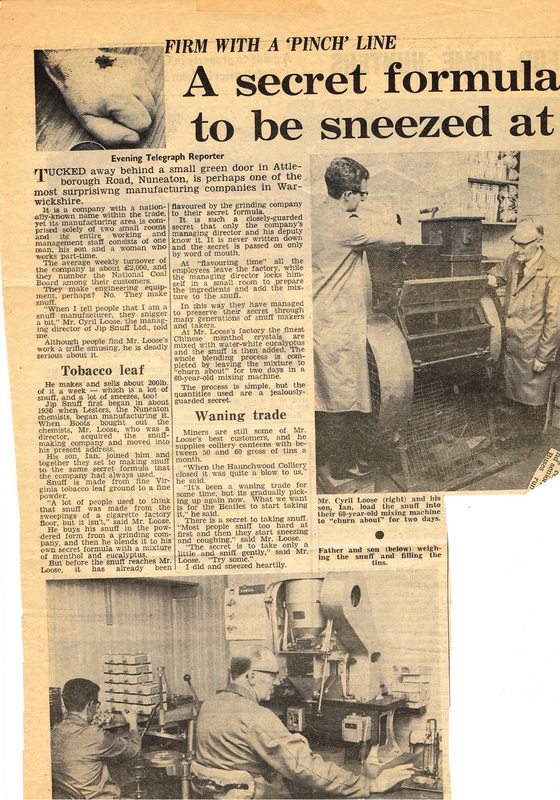

Jip Snuff (another one of Nuneaton's many industries)

Listers Mill was built in 1858. Listers manufactured velvet and worsted plush.

Listers Mill, Attleborough. This was built in 1858 by Thomas Townsend, a cotton manufacturer, and when Thomas Townsend died the mill was taken over by Messrs. Listers & Co. of Manningham near Bradford in 1892. The owner of this business was Samuel Cunliffe Lister, 1st. Baron Masham (1815-1906) worsted plush manufacturers. Worsted plush is a soft woven cloth with a thick deep pile with a luxurious feel to it. Extensively used in furniture manufacture. At that time the Manningham mill was the largest weaving mill in the world and the establishment of the company locally in Attleborough brought much needed employment to the Nuneaton area. The transferral of the business to Nuneaton was caused by the need to diversify their business away from the Manningham factory due to a number of strikes suffered by the Bradford mill to prevent the whole production being lost. The general manager was Mr. Fred Frankland who transferred down to Nuneaton. Spools of yarn from Manningham were shipped to Nuneaton by rail and arrived on the Midland Railway at Nuneaton Abbey street station goods yard where they were collected in later years by Lister's Maudsley lorry. The mill's chimney was 125'0" high. Fred Frankland who was the manager at Attleborough 1905-1922. Fred's son Harry was the mill engineer. The mill was extended in 1898, 1910 and 1920. In 1958 it employed 370 people of which 70% were women. There was 21,000 sq. yards floor space and the mill site covered 4.5 acres. It was divided into three departments the silk throwing floor, velvet weaving sheds and the dyeing and finishing section. Raw silk was imported from Japan at one time. in 1969 the mill employed 180 people of which 75% girls. (Peter Lee)

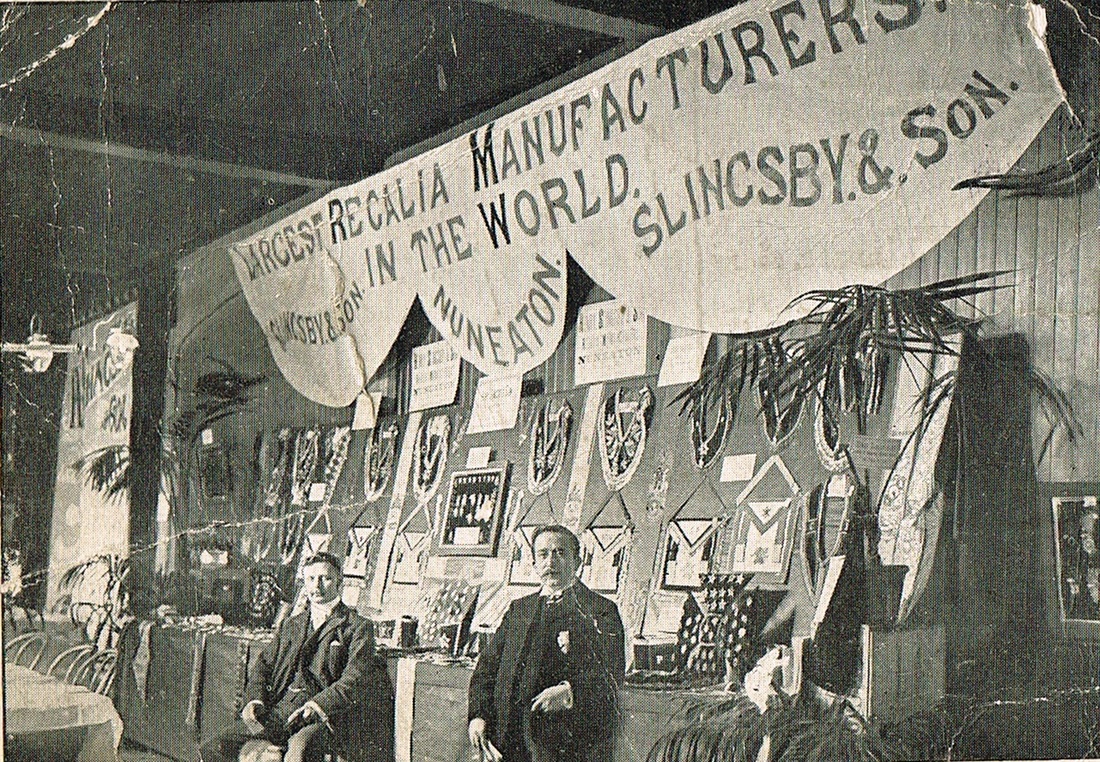

Slingsby's & Son was one of the last silk manufacturers in Nuneaton producing regalia, banners, silk military articles. It was taken over by Franklins of Coventry about 1948.

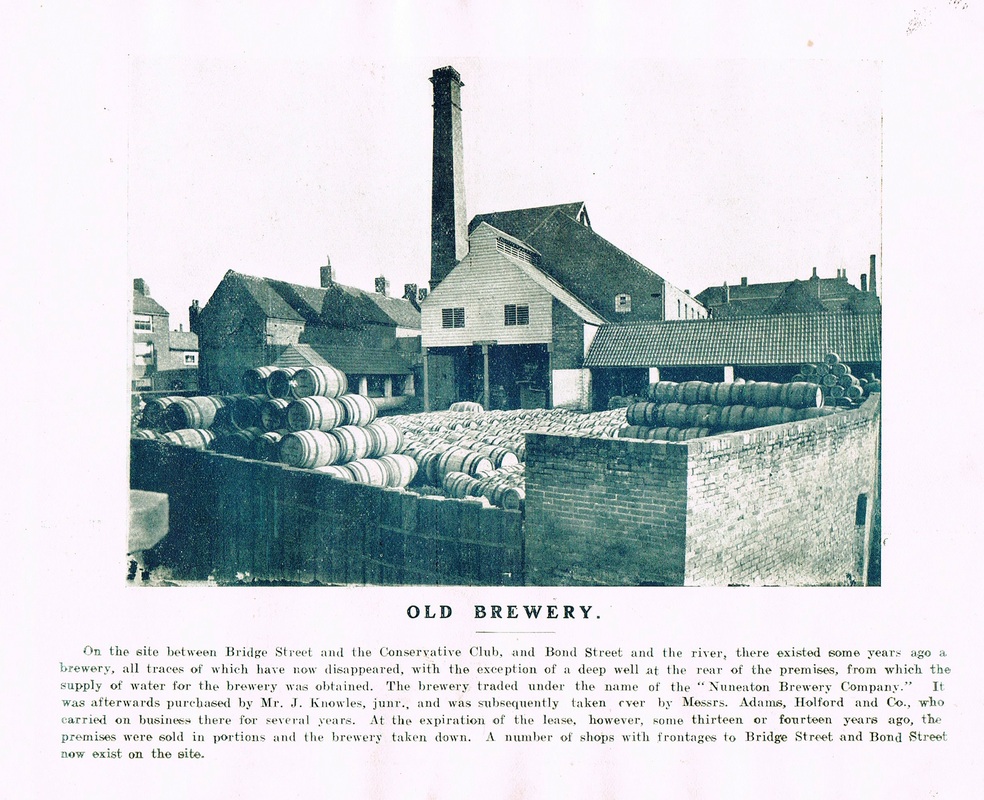

Nuneaton Brewery Co. (later Adams Holford & Adams)

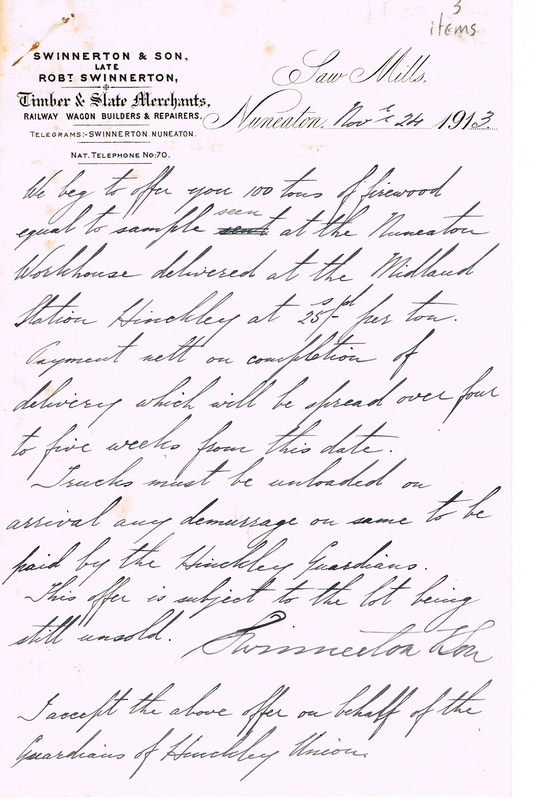

Nuneaton Timber Co. Ltd

Formerly Swinnerton & Son

Previously Robert Swinnerton

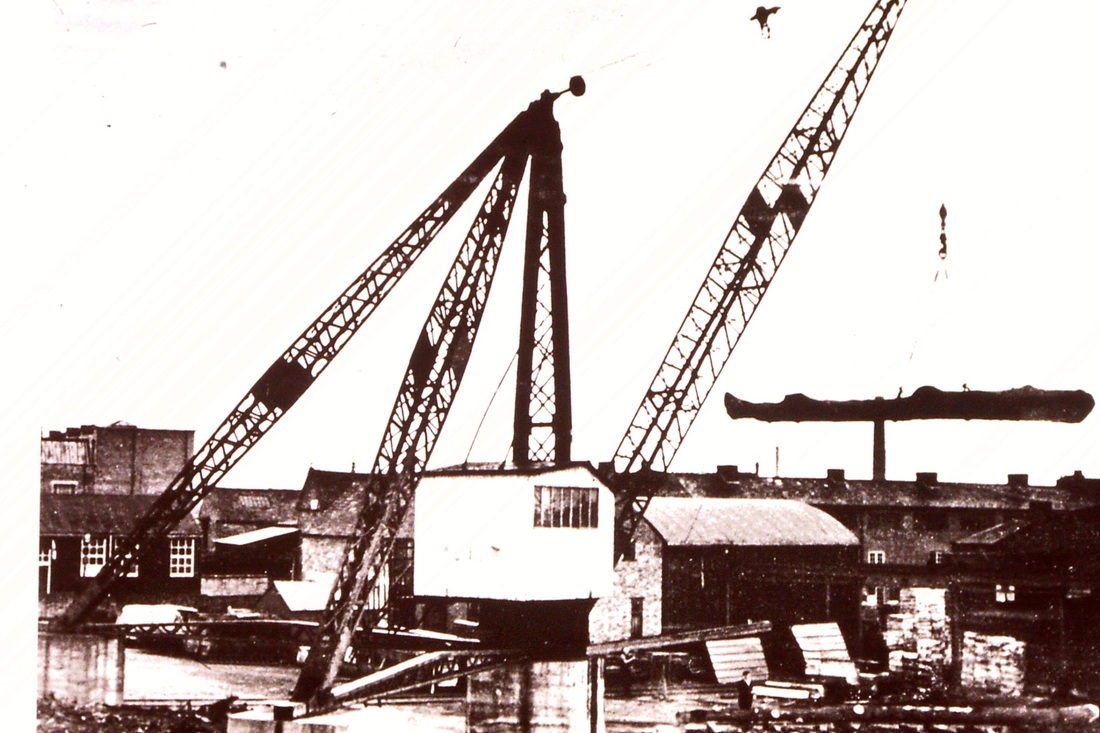

One of Nuneaton's landmarks was a huge crane which stood near the station. It was part of the iconic townscape for many years. It was owned by the Nuneaton Timber Co. Ltd and used to unload or load timber either from/to railway wagons or from lorries. There was a private siding into Nuneaton Timber's yard from the station goods yard. The timber yard was originally owned by the Swinnerton family and their yard was right next to the Trent Valley station. This location halfway between Stafford and Rugby on the Trent Valley line meant that they became timber suppliers and builders of ballast wagons for the new railway when the track was being laid down. They went from strength to strength, and around 1919 the private business of Swinnerton & Co was converted into a limited company. The Nuneaton Timber Co. Ltd which prospered for many years afterwards. An important part of the commercial life of the town. Isaac Swinnerton built the row of weavers houses on the opposite side of Regent Street (originally known as Brick Kiln Lane) in 1818. These were demolished in the 1950's and Nuneaton Timber Co. expanded over the road to the site of the current Dunelm store. A name closely associated with Nuneaton Timber Co. Ltd in the 20th century was Harry Cleaver. He also owned Yoxalls the famous café and bakery in Abbey Street after Walter Yoxall retired. In this photo which is taken from the Leicester Road bridge you can see the crane in action. Also on the extreme left a wooden structure which was for many years Nuneaton's Labour Exchange. The crane was removed for scrap and today one of its concrete plinths is the only remnant of Nuneaton Timber Co. The Timber Co. also had a branch near Wilnecote.

A group of three craftsmen carpenters employed at Nuneaton Timber Co. c. 1919/1920.

Left to right - ? / Fred Pallett / George Farndon. George Farndon was on secondment to the Nuneaton Timber Co. from his father's business - George Farndon & Son, when the Timber Company was short of skilled tradesmen. (Kay Farndon)

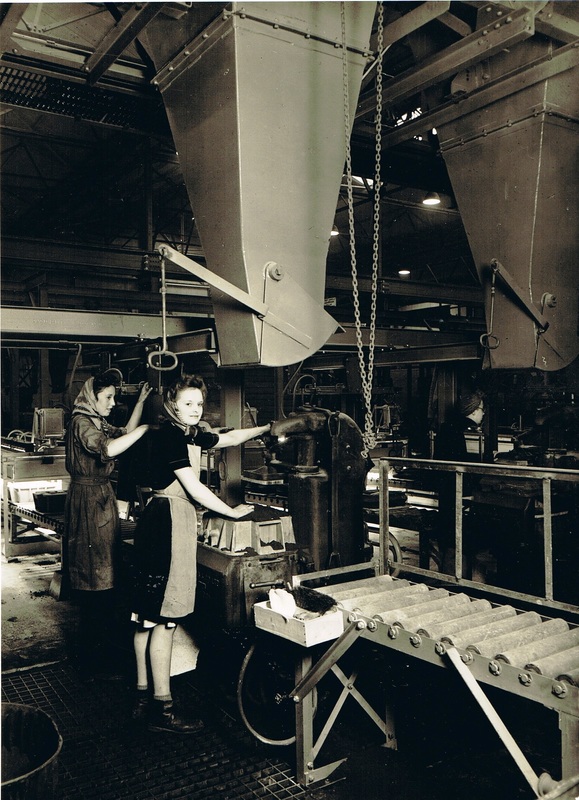

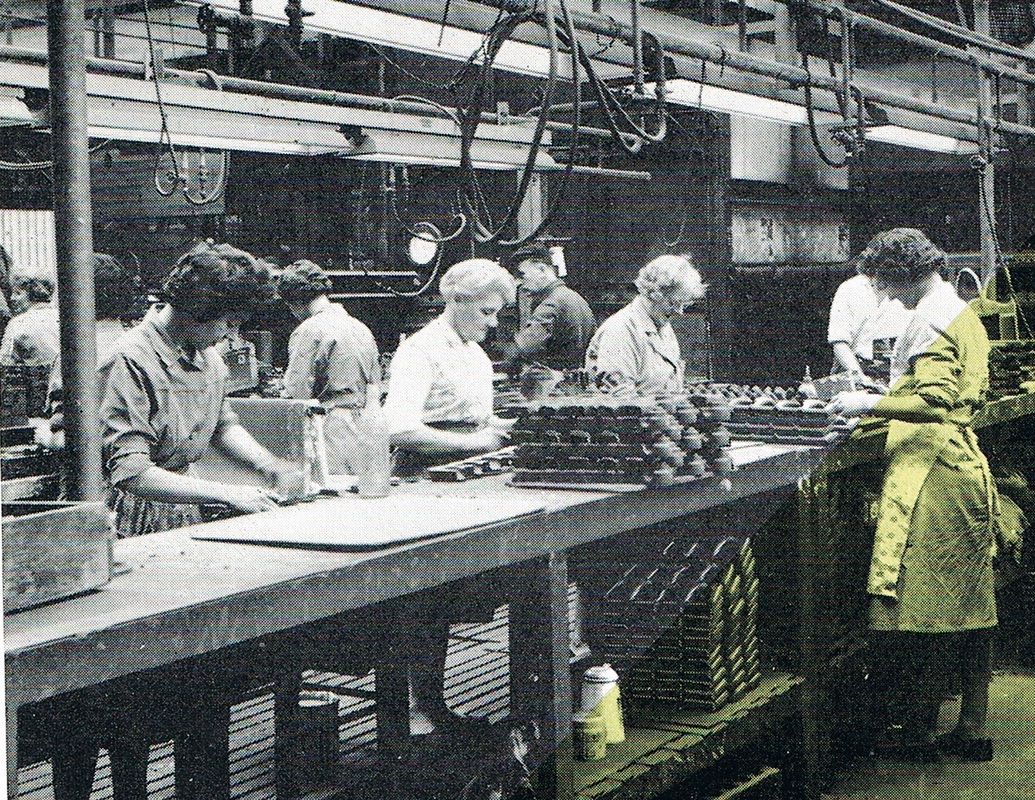

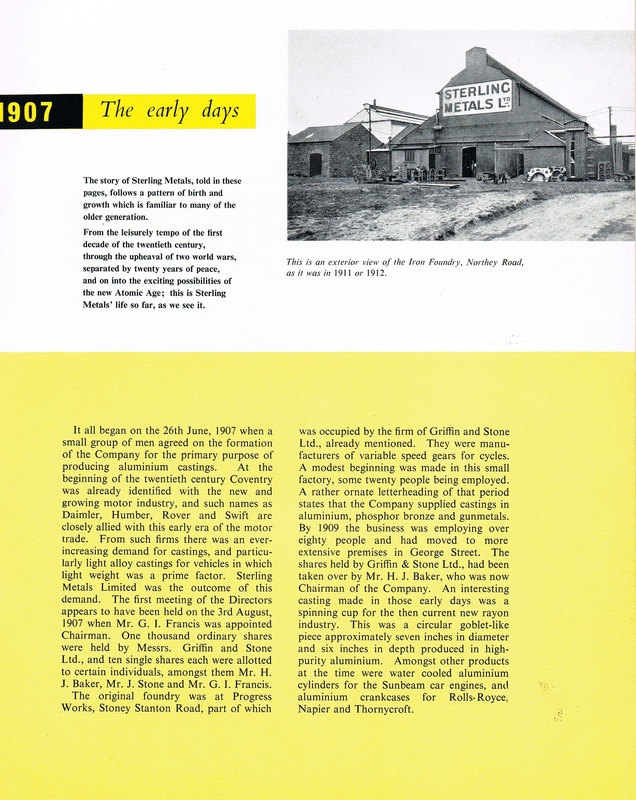

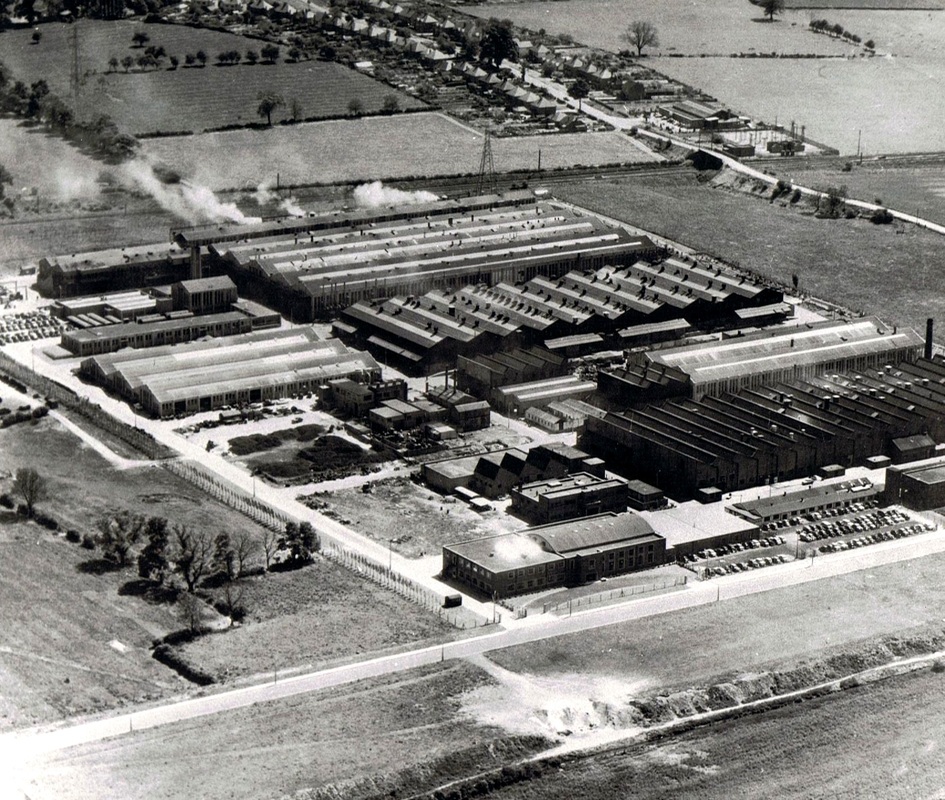

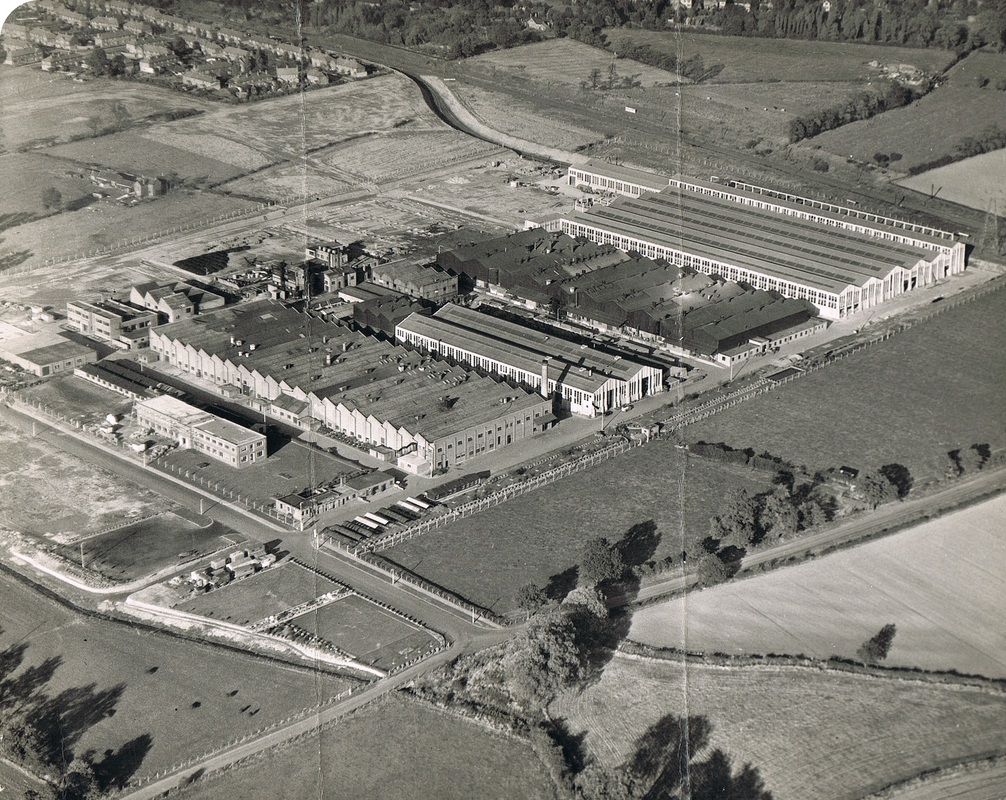

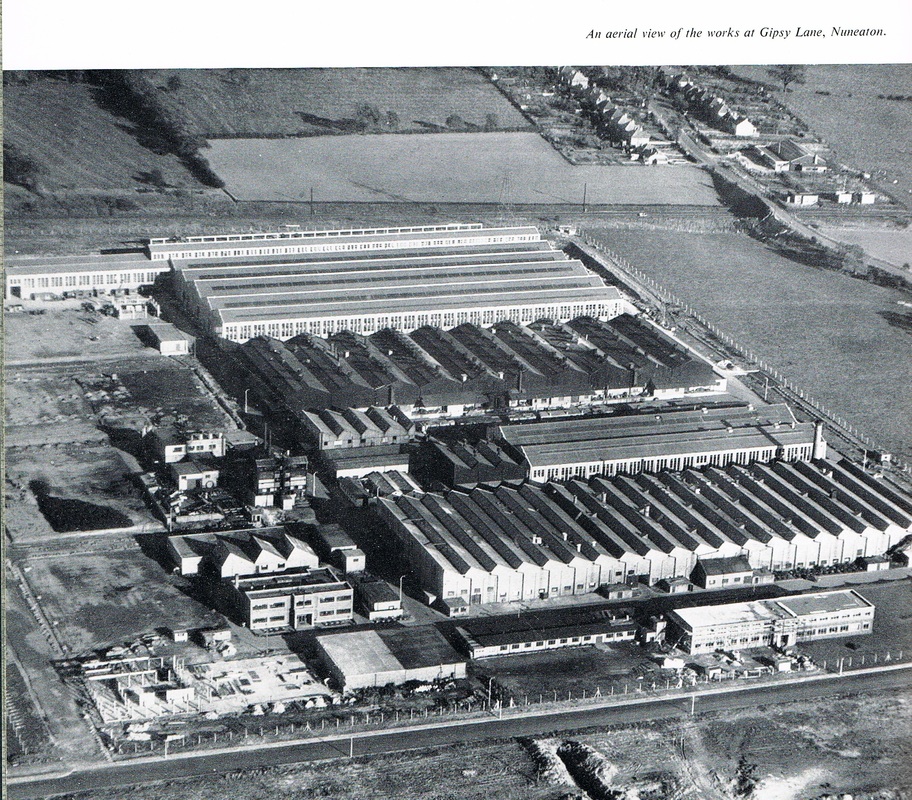

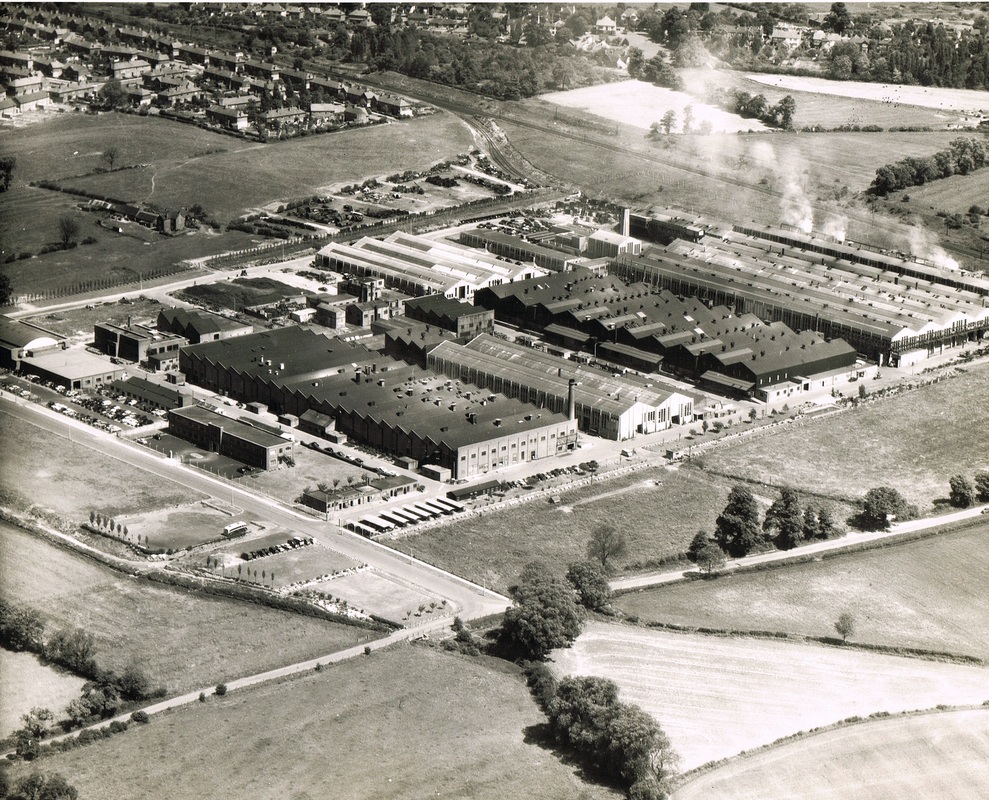

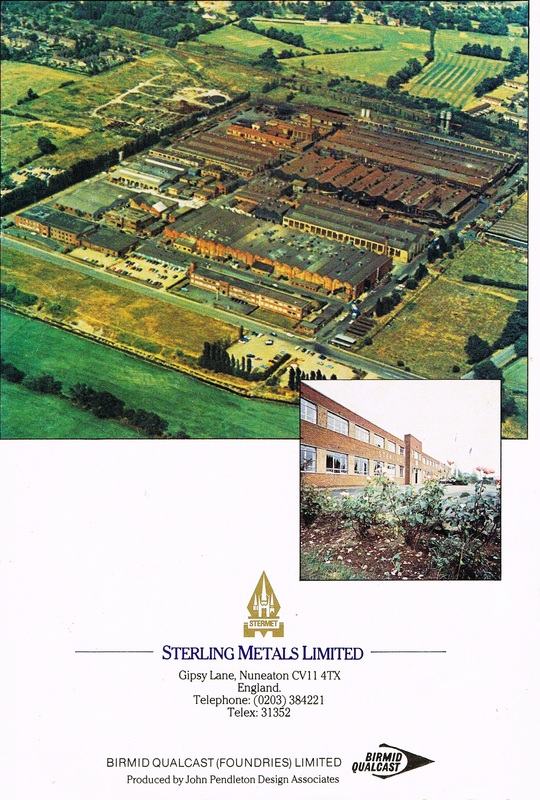

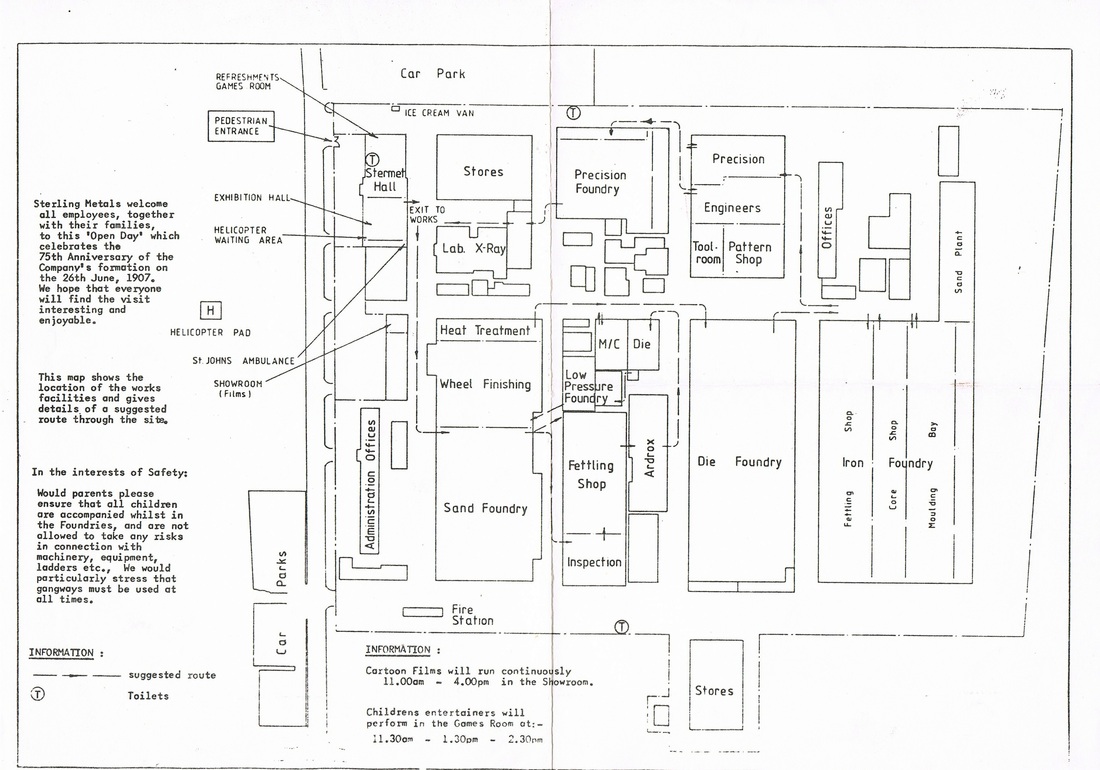

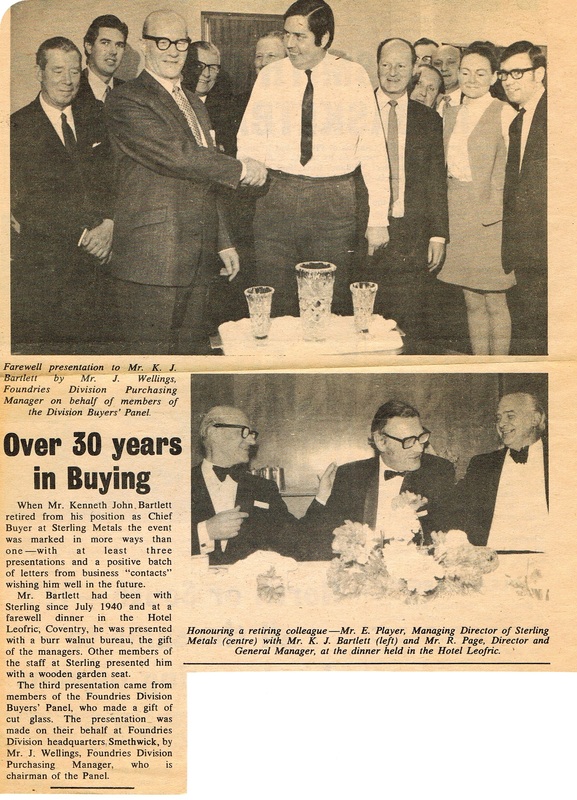

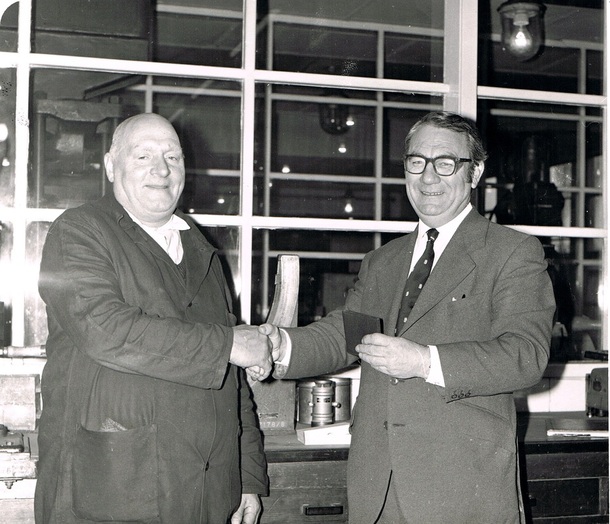

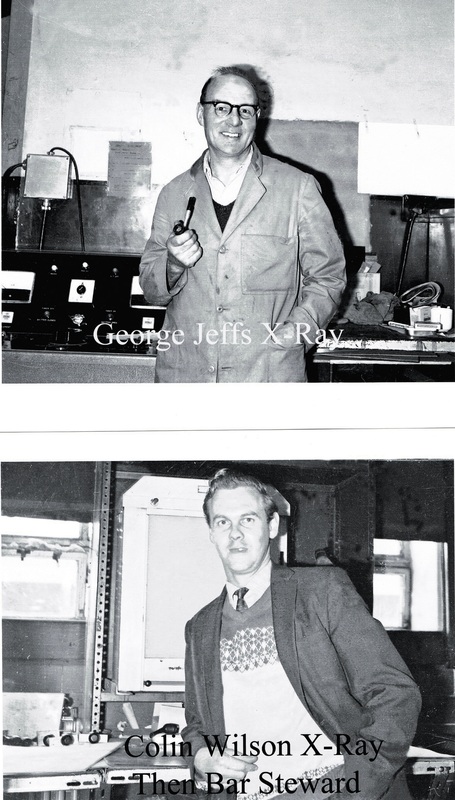

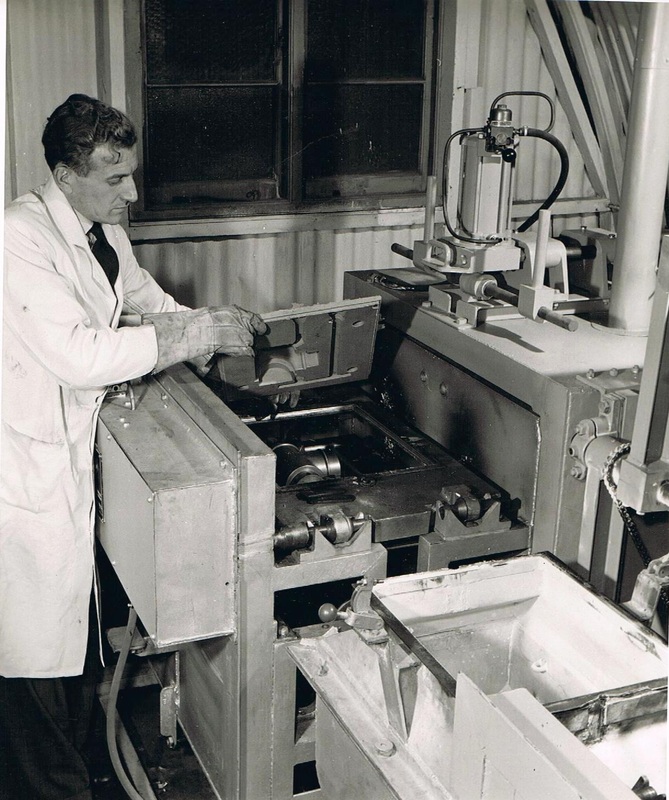

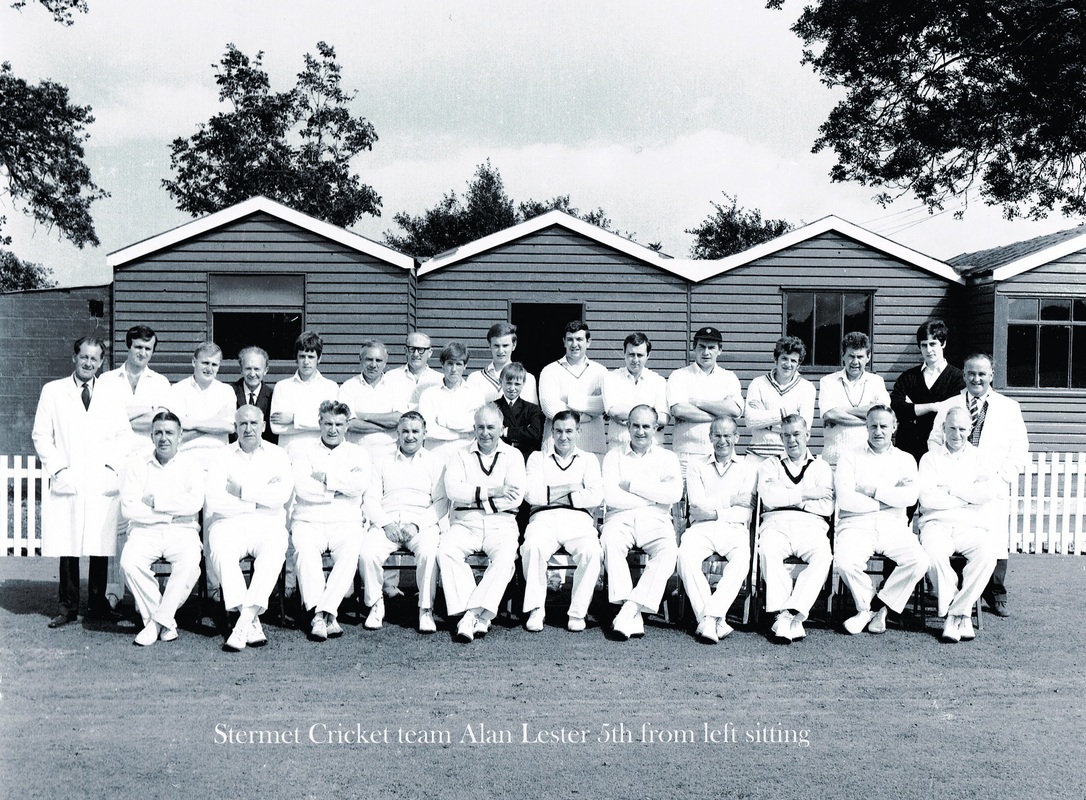

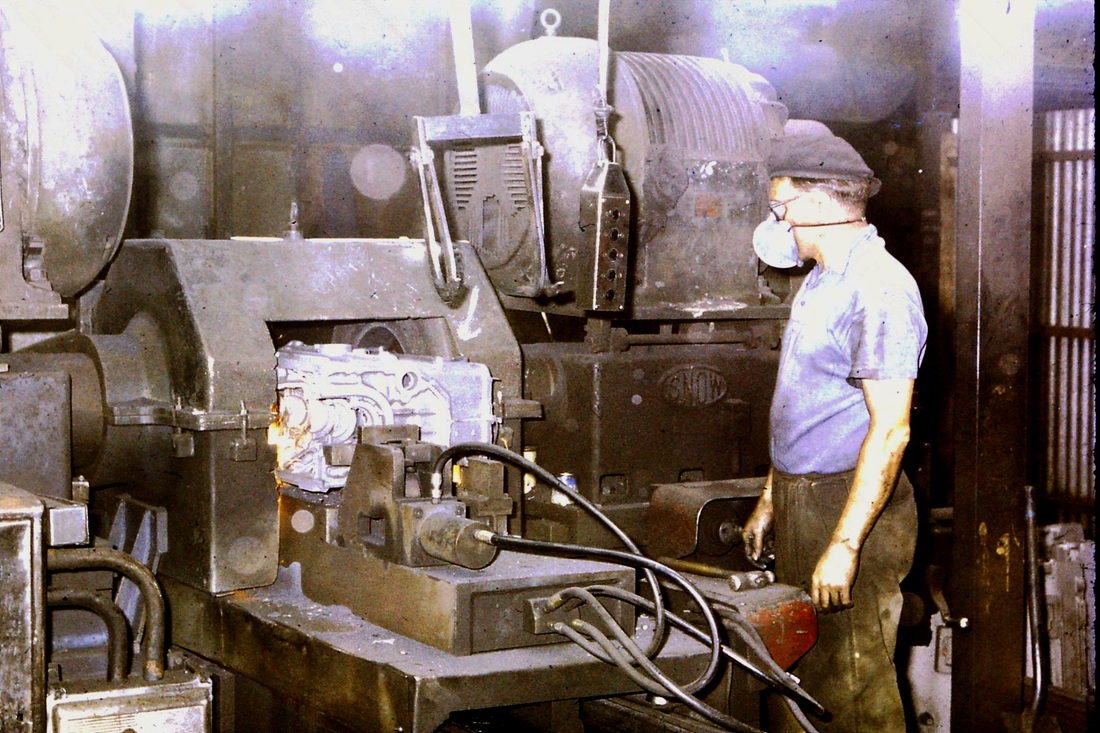

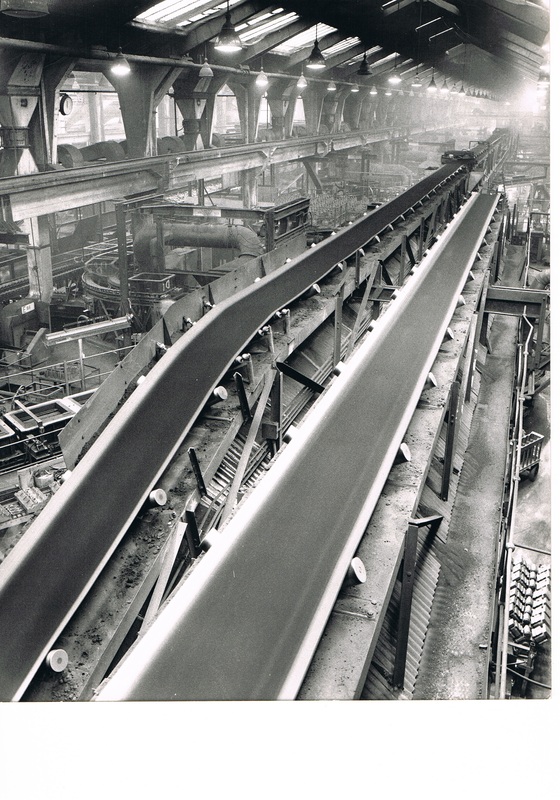

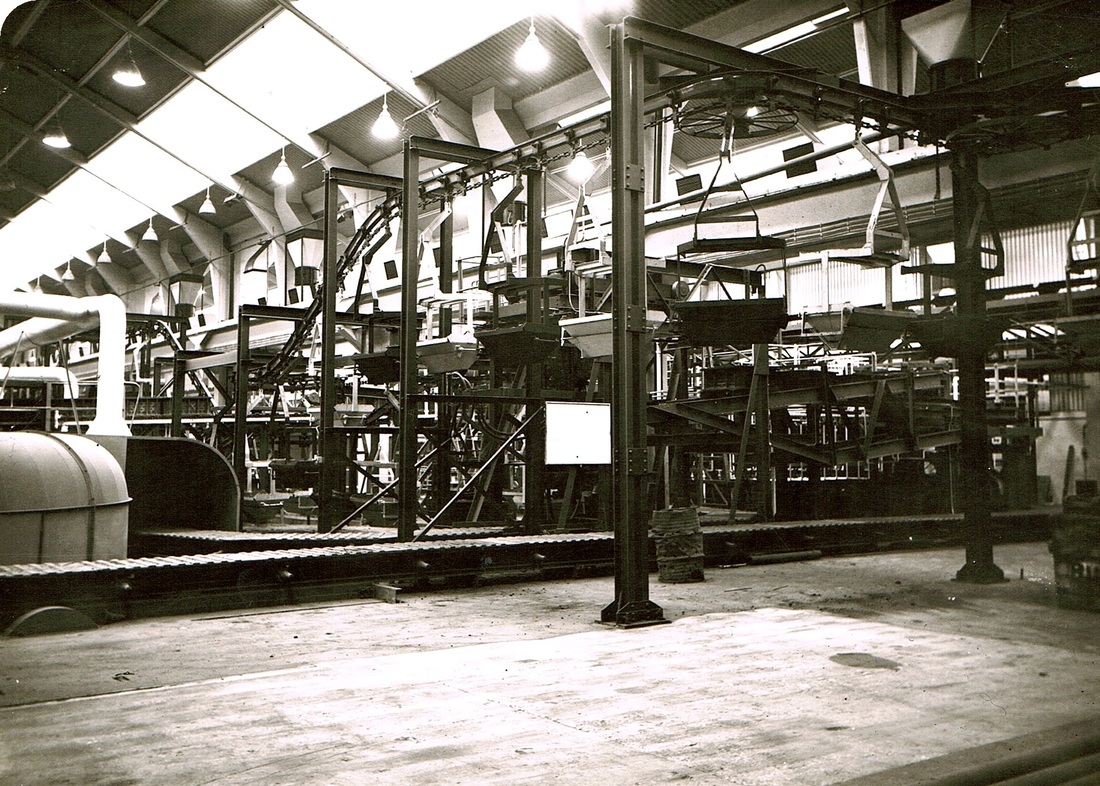

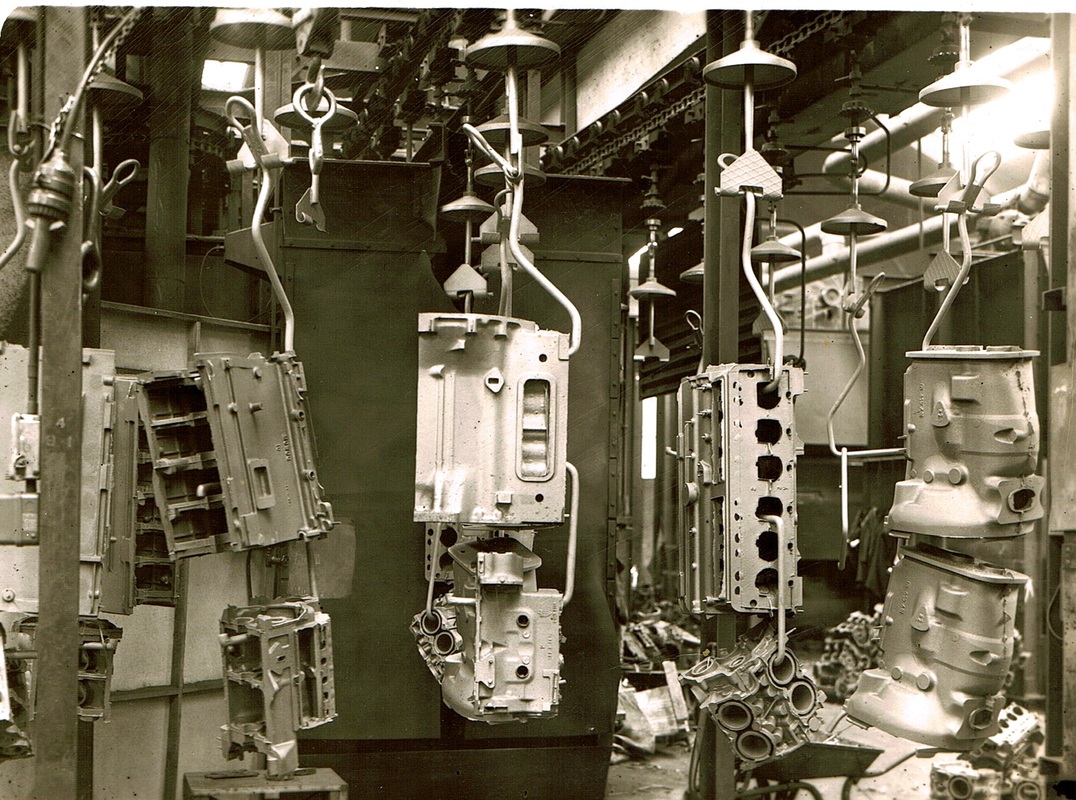

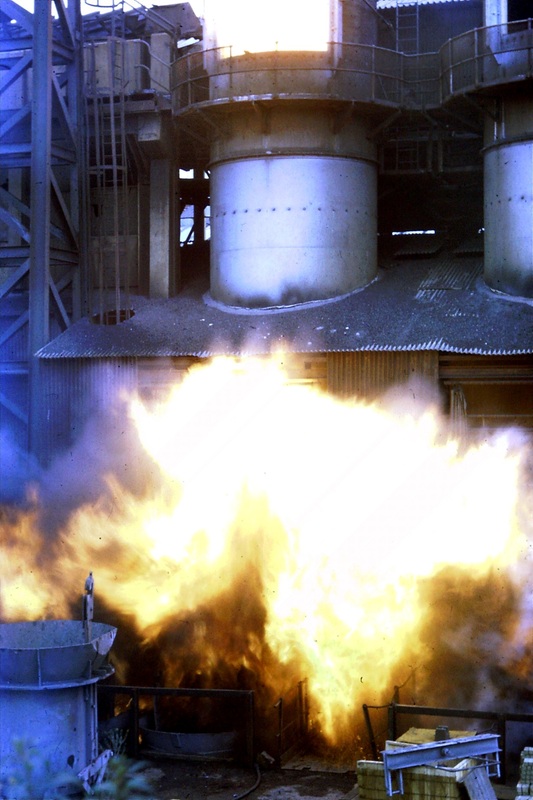

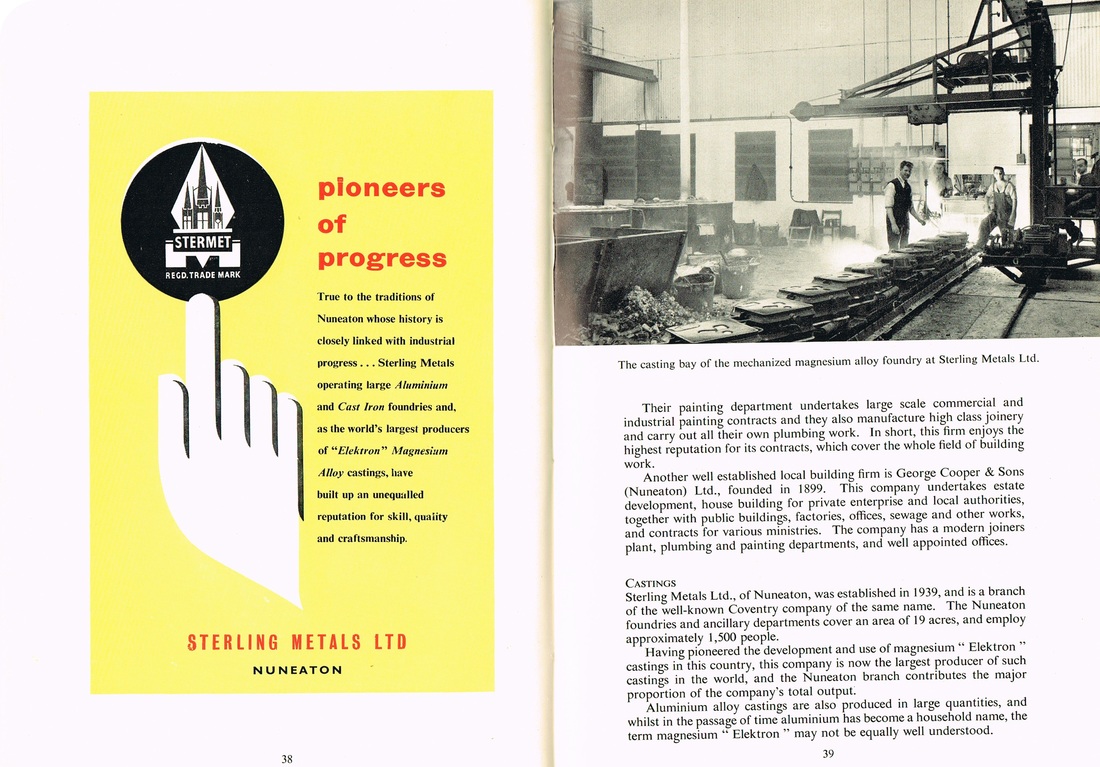

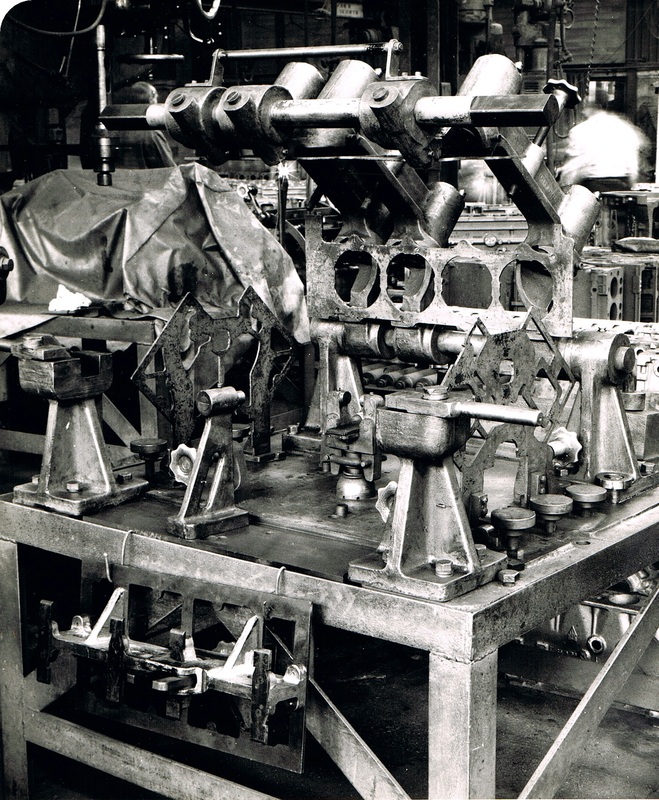

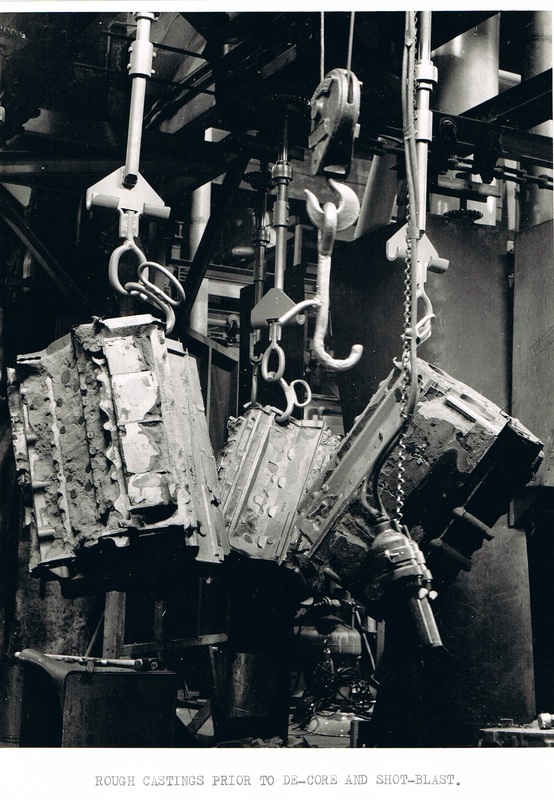

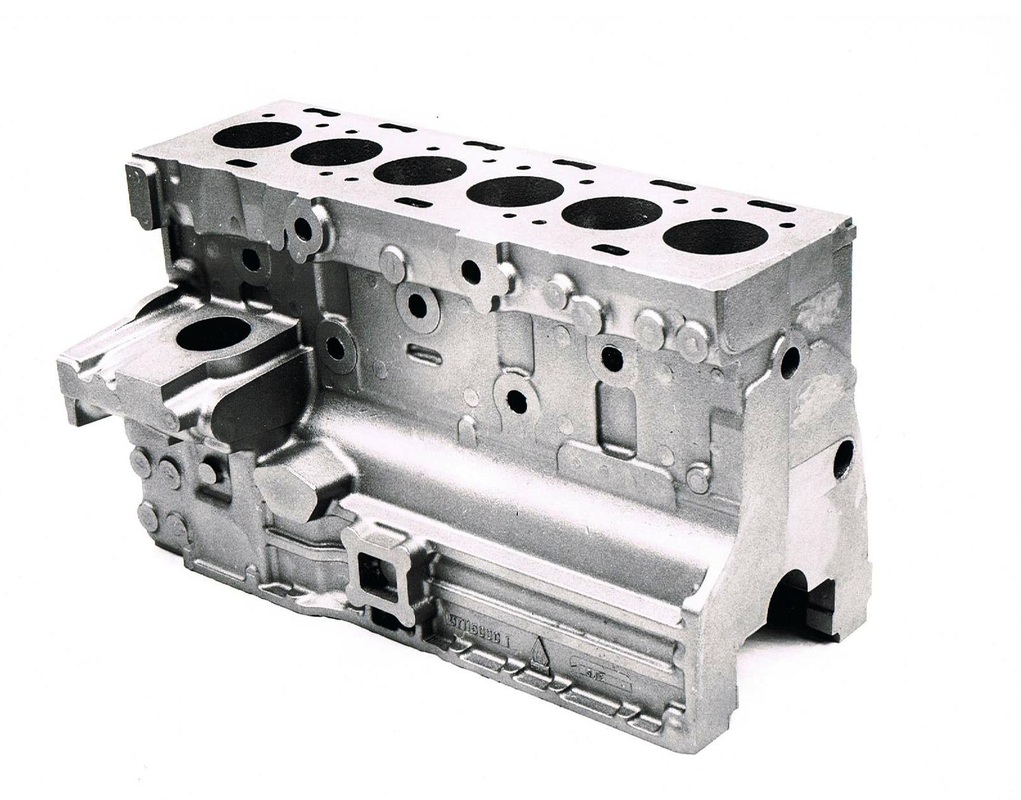

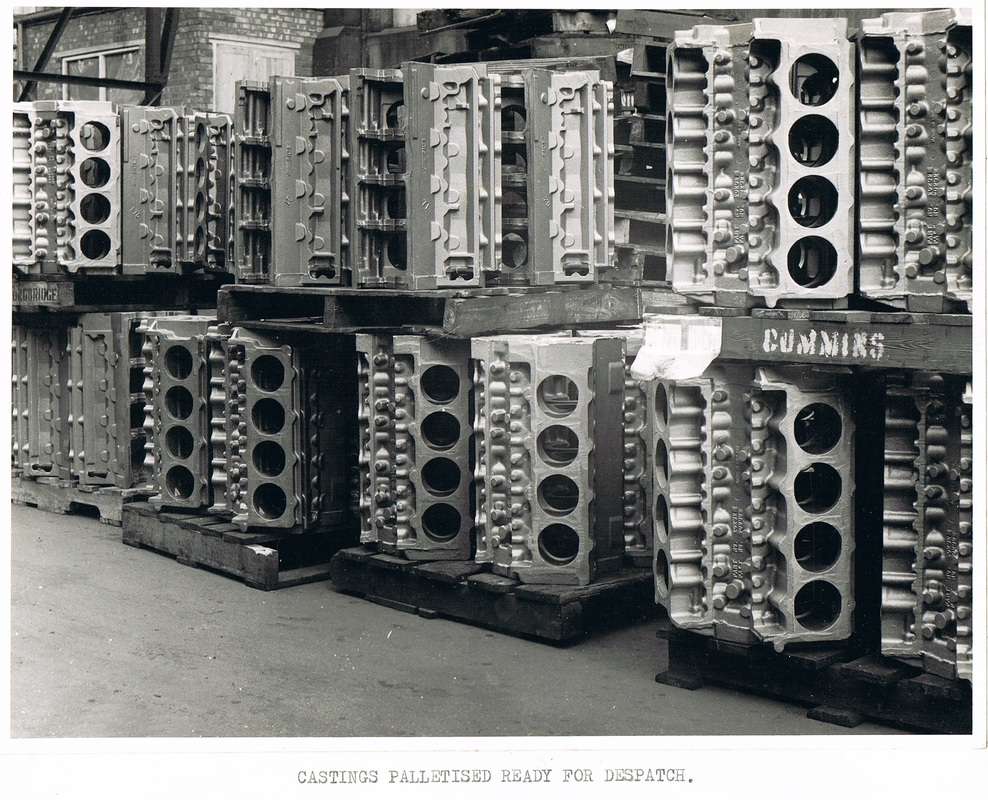

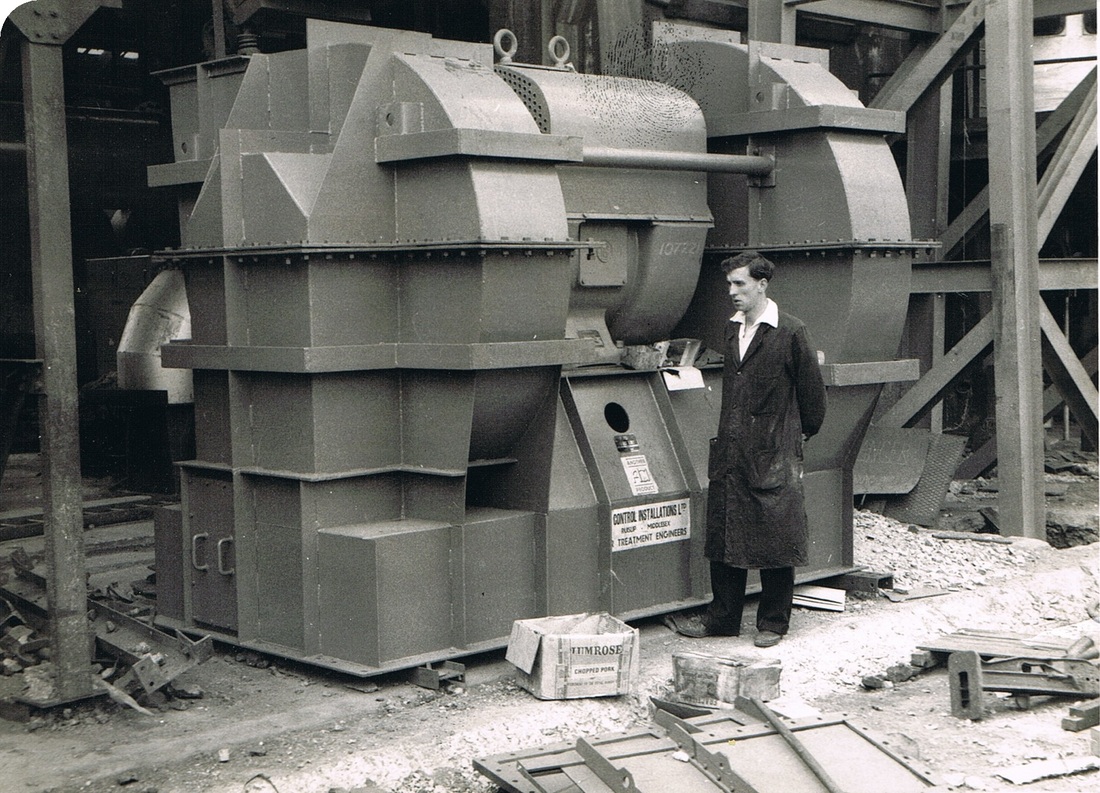

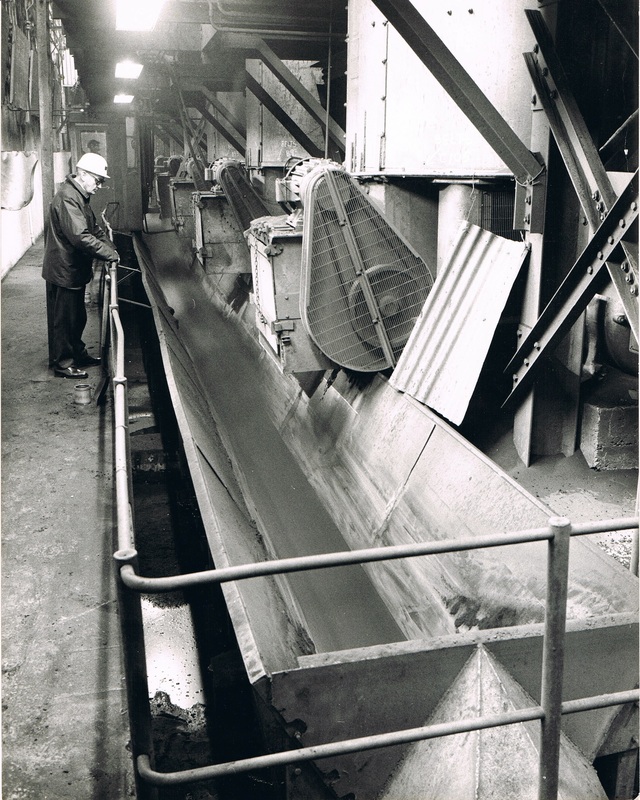

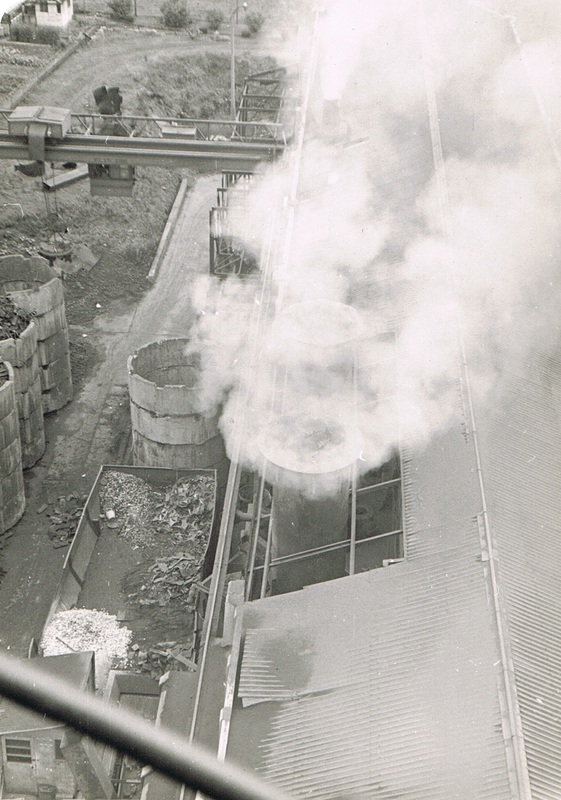

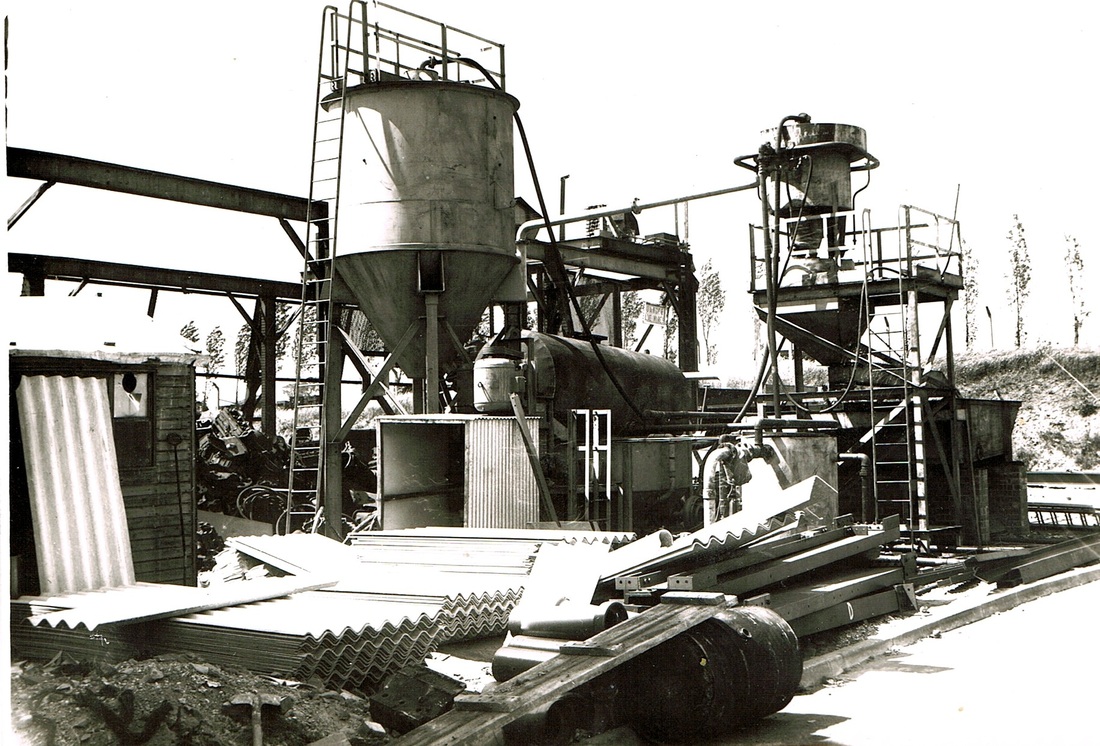

Sterling Metals, Nuneaton's biggest employers at one time with over 3000 employees. An important manufacturing business with well paid jobs which was a catastrophic loss to work opportunities in the area when it closed. Does anyone recognise the shops and processes? There will be a further sequence of photos in the People - Mystery Photos section. Please identify the people working at Sterling in those pictures if you can. (And let me know PL)

The following Sterling Metals photos are uncaptioned at present as I hope you can recognise someone and the processes being undertaken. It does emphasise the high drama of a busy foundry and the stress of life at the Sterling.

When the iron foundry was built in 1955 a siding was put in from the Trent Valley main line (on the right) controlled by Attleborough box. Iron ore was brought in by rail to be smelted in the foundry. The problem was that in order to gain access to the siding trains had to travel "bang road" or travelling wrong road brake van first up the TVR which was a tricky operation in view it was mixing with passenger and freight traffic on the busy main line. Electrification put paid to this nonsense and the points taken out as BR did not want awkward propelling movements mixing with 100mph electric trains. This is the very first train to enter Sterling Metals siding backing down from the down main line.

Sterling Metals ballroom - The Stermet Hall

Tansey's needle works made industrial needles for knitting machines and cloth manufacture.

Tansey's Needle Works c. 1958. Halfords store now occupies this location in Newtown Road, Nuneaton. L. Tansey & Co. Ltd was established in 1886 making catch needles for the hosiery industry. These premises were later used by the National Coal Board as laboratories. This was one of an extensive set of photographs commissioned by the NCB Area Laboratories at the time they moved into their new lab in the early 1950's and re-used the former needle works. (Peter Lee Collection)

Union Wool & Leather, Nuneaton

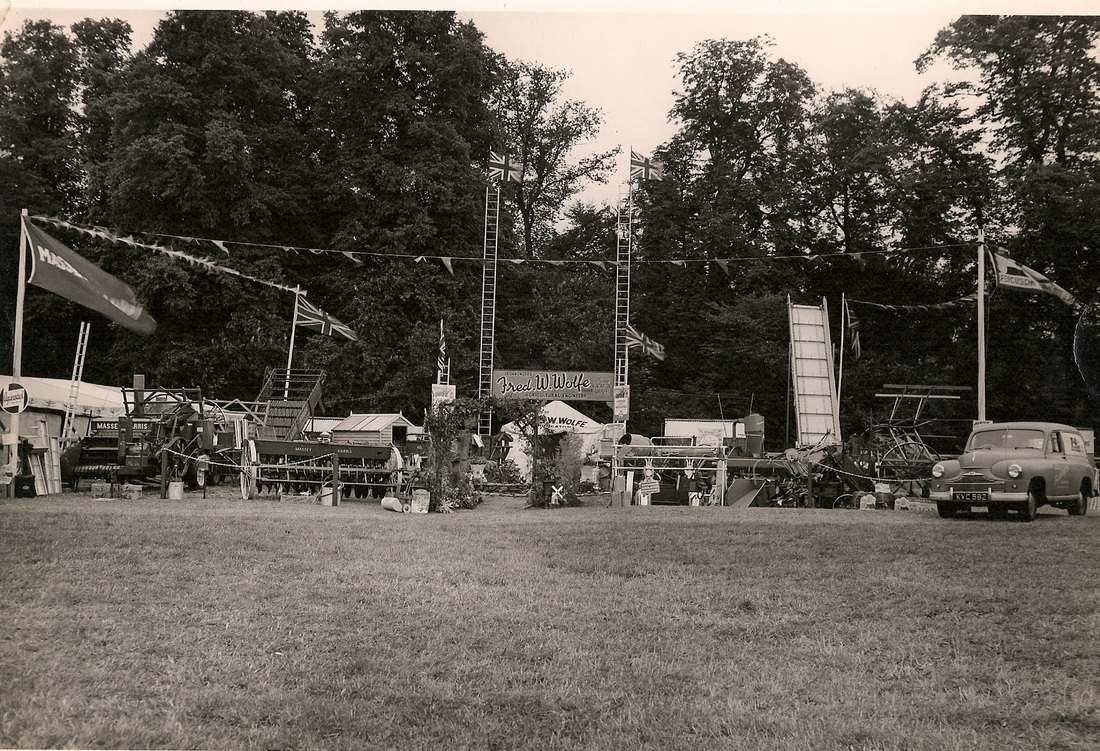

Fred W. Woolfe, Ironmonger and Agricultural Engineer, Nuneaton.

Fred Woolf were agricultural merchants servicing the farmers in the North Warwickshire area from their base in Harefield Road, Nuneaton (where Nuneaton bus station is now). They were well placed to do so because their premises were exactly opposite the Nuneaton cattle market so the local farmers having brought their livestock to market could conveniently call in. For many years Fred Woolf attended agricultural shows with is wide selection of merchandise and he kept photographs of his exhibits, which are featured here.